Premium Material Selection

Key Features and Advantages

Materials Define Your Brand Positioning

1. Material Choice Signals Brand Level

Leather grade, texture, and finish instantly communicate whether your brand sits in the premium, mid-range, or entry-level market.

2. Materials Shape Pricing & Customer Perception

From full-grain leather to alternative materials, material selection directly impacts unit cost, retail pricing, and perceived value in your target market.

3. Smart Materials Enable Scalable Production

The right materials balance design intent, MOQ, lead time, and consistency—supporting both brand launches and long-term growth.

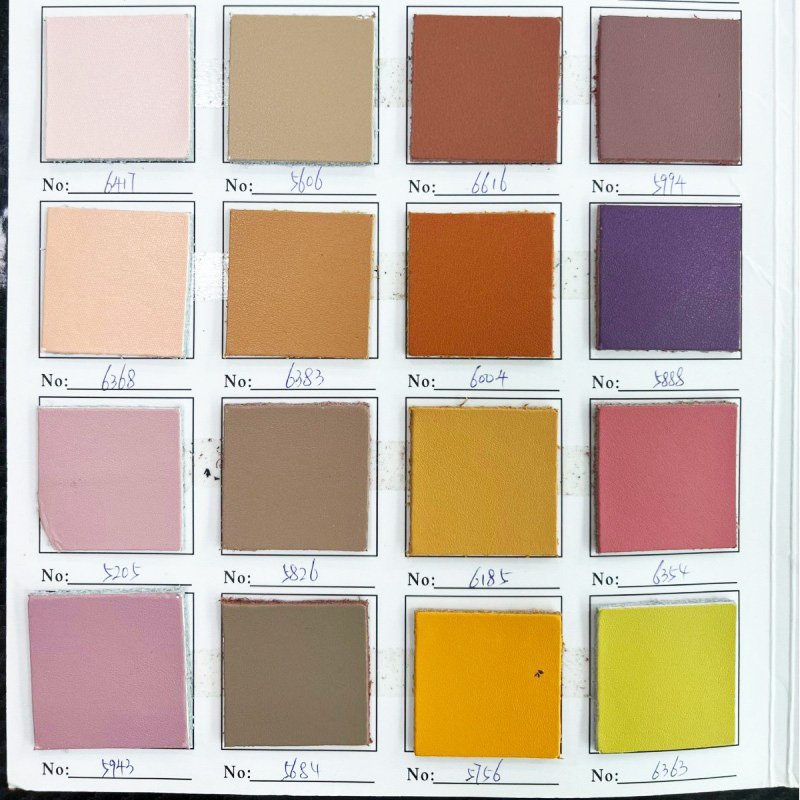

Customize the Materials That Fit Your Brand

Customize leather type, texture, color, thickness, and finish to match your brand vision, target customers, pricing strategy, and production scale. Our flexible material options support both brand launches and long-term growth across different markets.

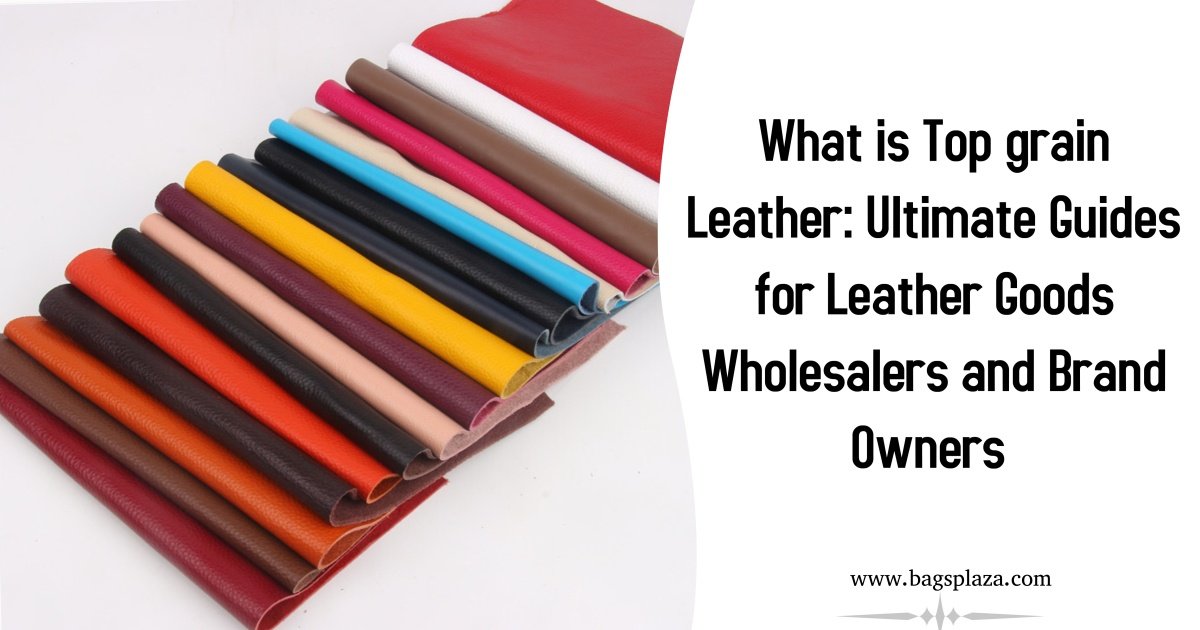

Materials You Can Choose for Your leather bags

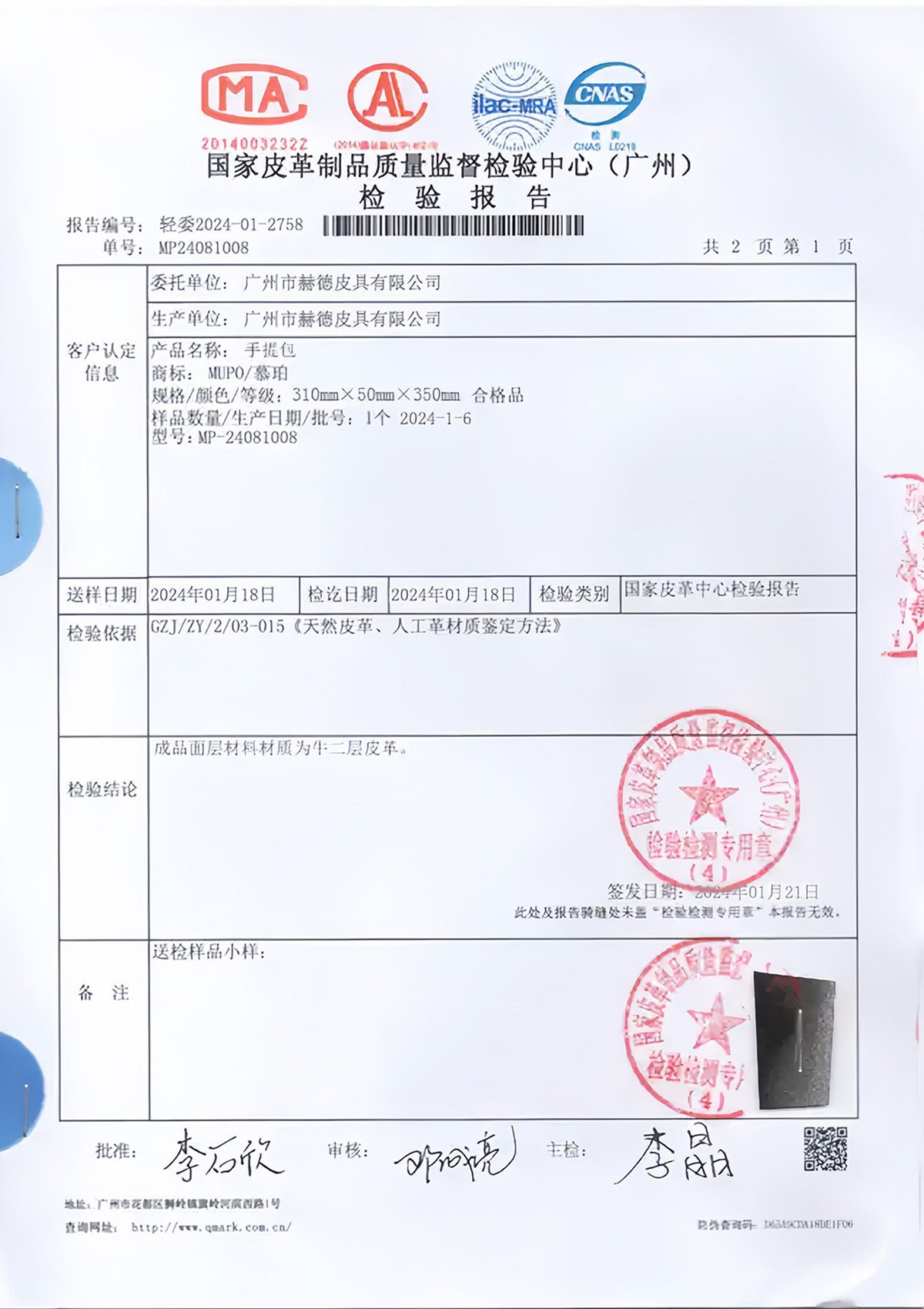

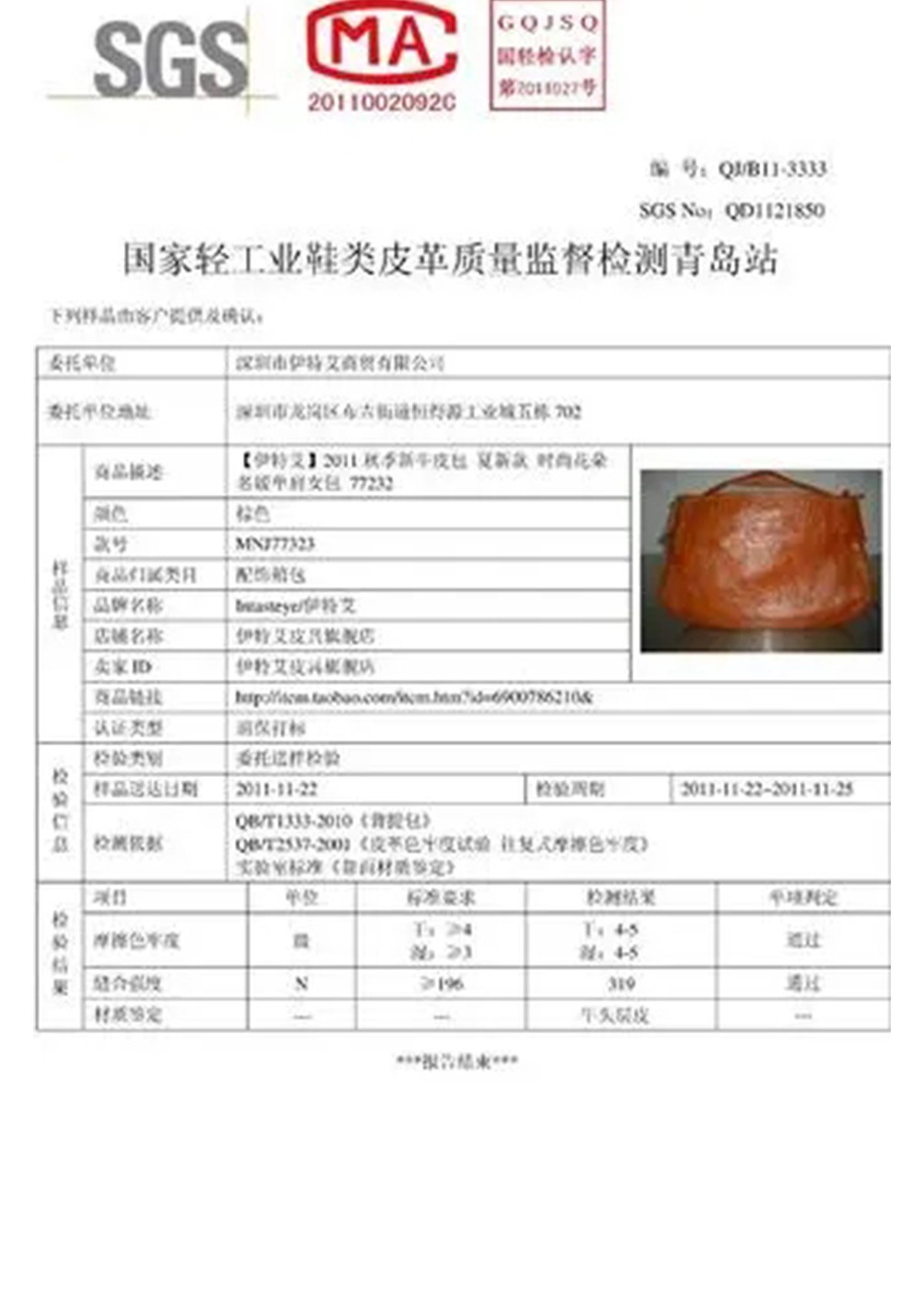

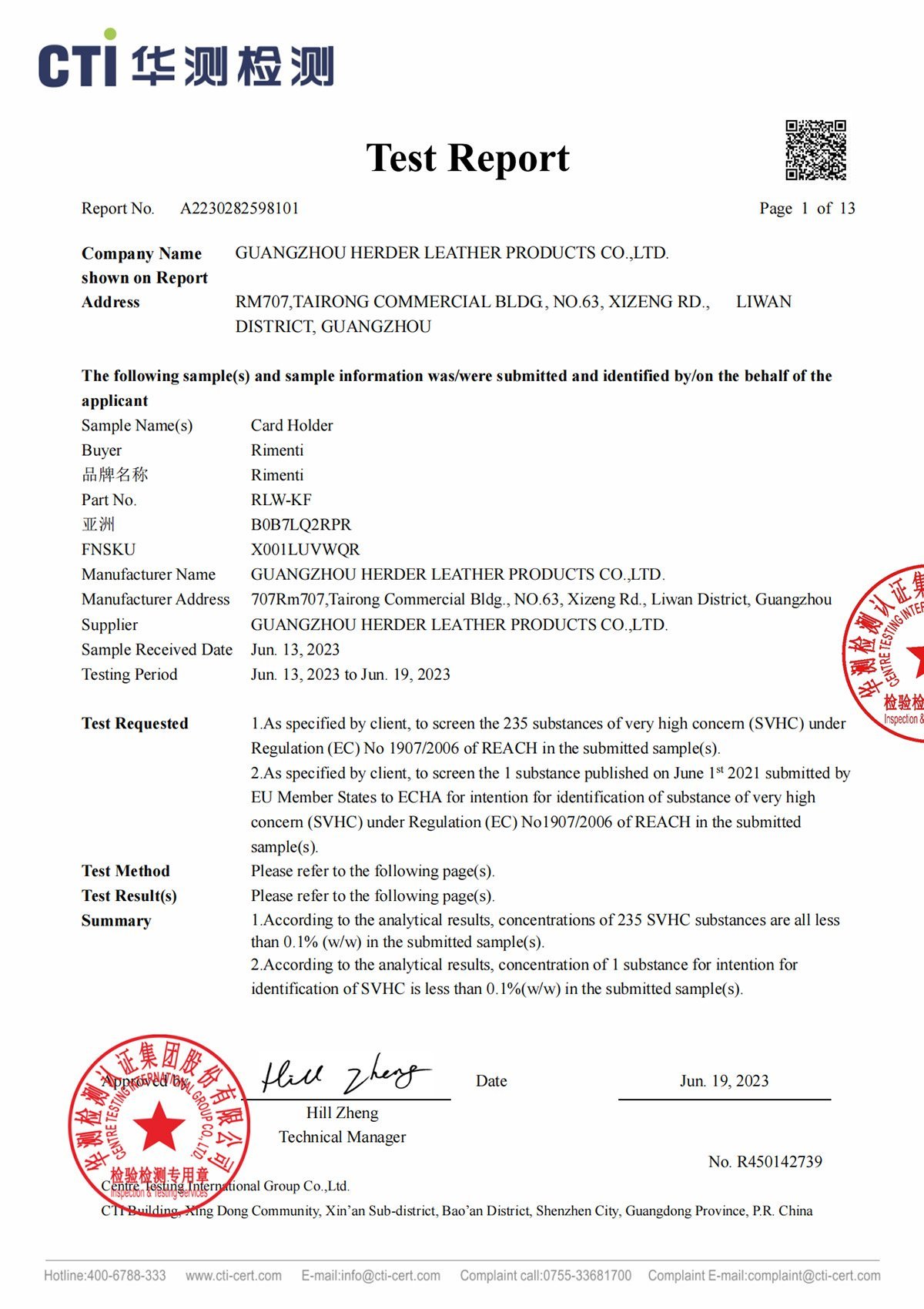

Mherder always chooses premium quality materials that meet standards like CE, CA65, GRS, ITS, SGS, etc. We specialize in luxury and the finest genuine leather, such as Full Grain Leather, Top Grain Leather, Corrected Grain Leather, Split Leather, Nubuck Leather, Distressed Leather, etc.

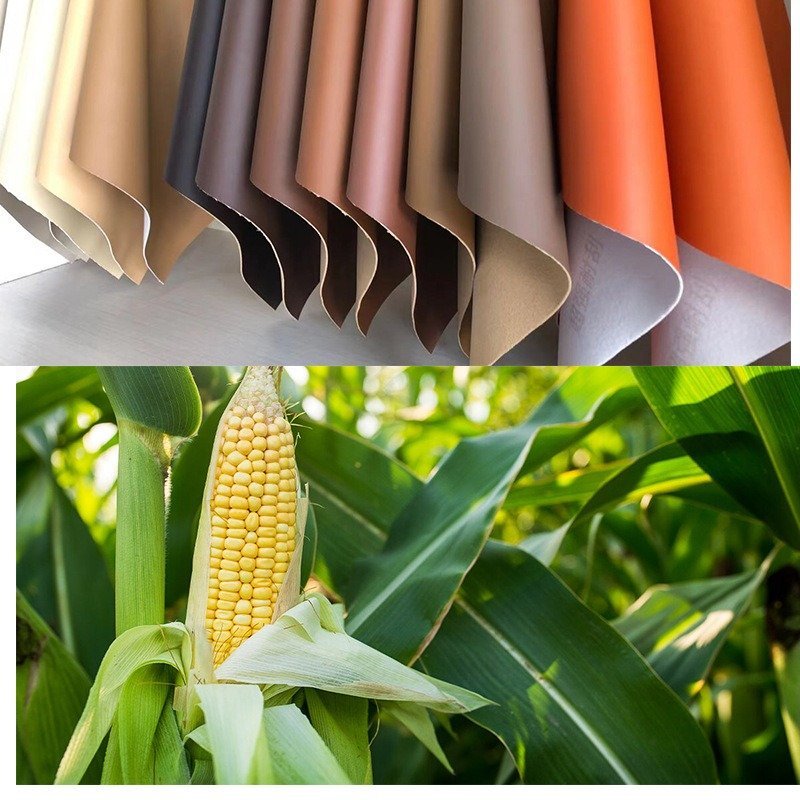

Eco-Friendly Materials for Responsible Brands

From vegetable-tanned leather to recycled and low-impact materials, our eco-friendly options help brands reduce environmental impact while maintaining consistent quality, durability, and refined aesthetics—ideal for responsible sourcing, scalable production, and long-term brand positioning.

Why Custom Leather Bag with

Mherder China

One-Stop Solutions for Custom Leather Products

Professional Leather Bag Wholesaler in China

We have 5000+ Stock Inventory Designs available for your options. We offer lower MOQ, starting from 20 pieces per style for your market, which can greatly lower your inventory risk. In addition, our ready-to-ship leather bags can be delivered to you in 5-7 days after payment.

Wait! Don't Miss Out!

Still not finding what you’re looking for? Contact our consultants for more available products.

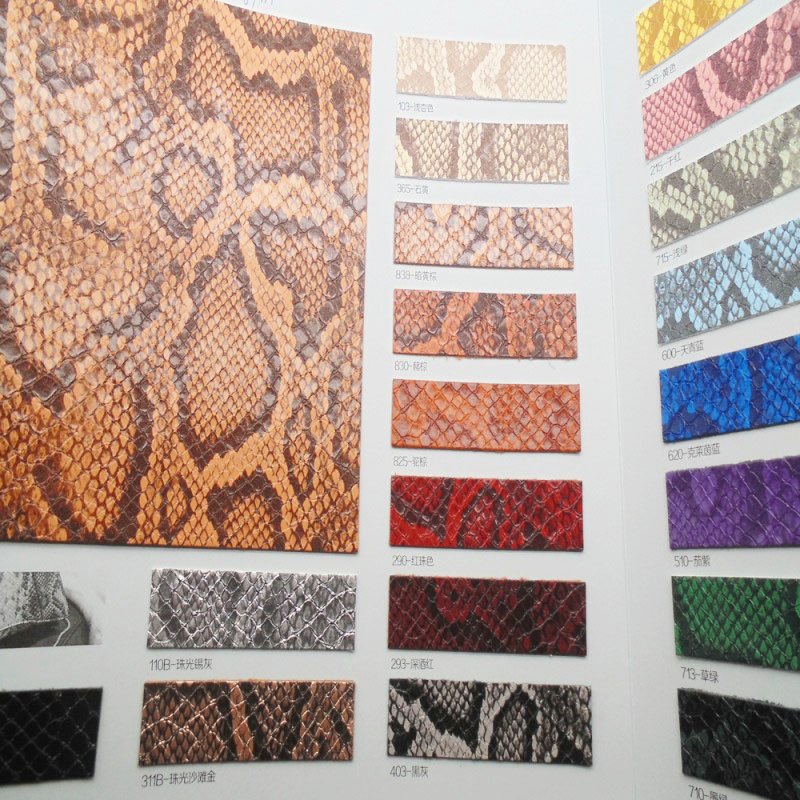

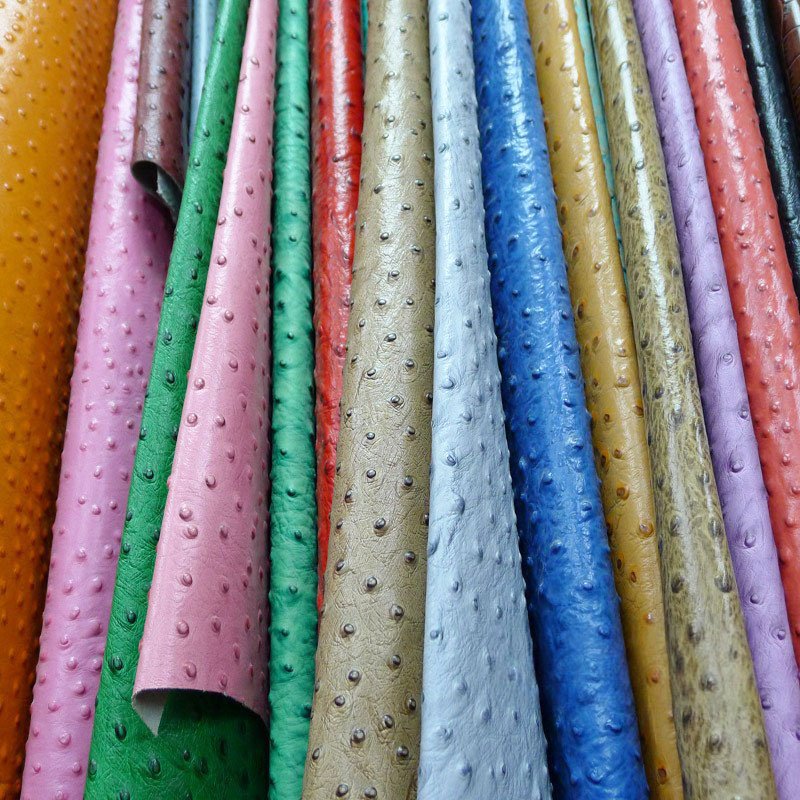

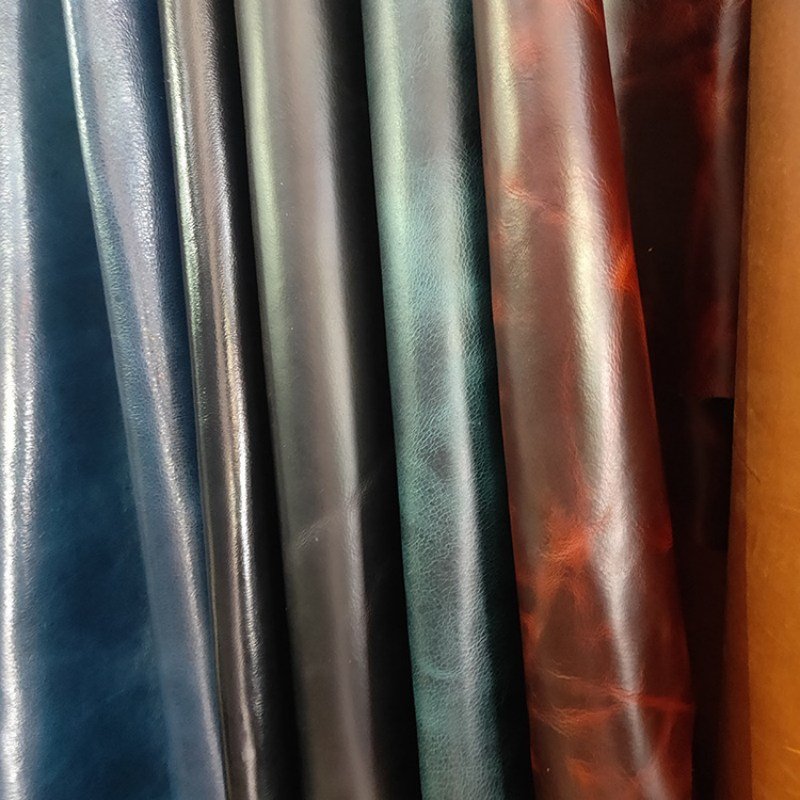

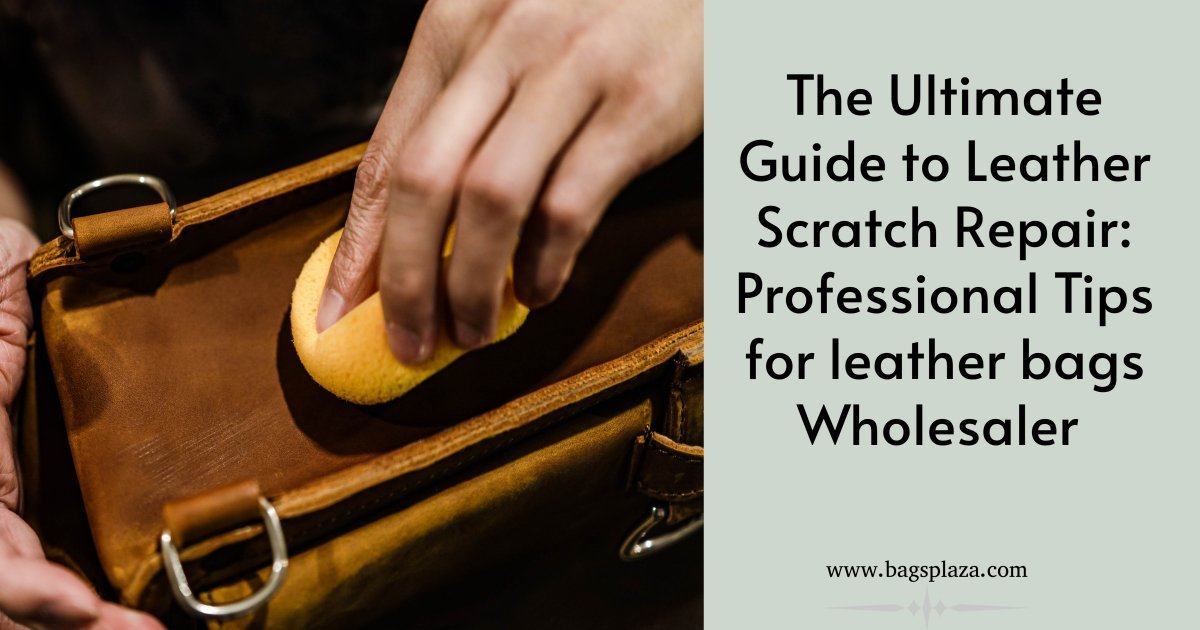

Leather Material Selection

Discover your perfect leather bag match – from top grain cow leather to soft lambskin, customize or wholesale bags that define your style. Whatever you need, we source the perfect leather for your order, tailored to your unique requirements.

Full-Grain Cow Leather Bags

Premium full-grain cowhide leather bags—naturally durable with visible grain marks, developing richer patina over time for enduring elegance.

Top-Grain Cow Leather Bags

Vegetable Tanned Cow Leather Bag

Vegetable-tanned cow leather bags age beautifully, developing a unique patina over time while being eco-friendly and free from harmful chemicals.

Distressed Cow Leather Bag

Distressed cow leather bags showcase rugged charm with intentionally weathered textures—pre-aged for vintage character while maintaining structural durability.

Split Leather Bag

LambSkin Bag

Lambskin bags embody luxurious softness with their featherlight suppleness, offering a buttery-smooth texture that drapes elegantly for effortless sophistication.

Horse Leather Bag

Horse leather bags combine exceptional durability with a distinctive grain pattern, offering a unique blend of strength and lightweight flexibility for enduring style.

Suede/Nubuck leather Bags

Experience the luxurious texture of suede/nubuck leather – a soft, velvety finish that adds refined elegance to any leather accessory or leather bags.

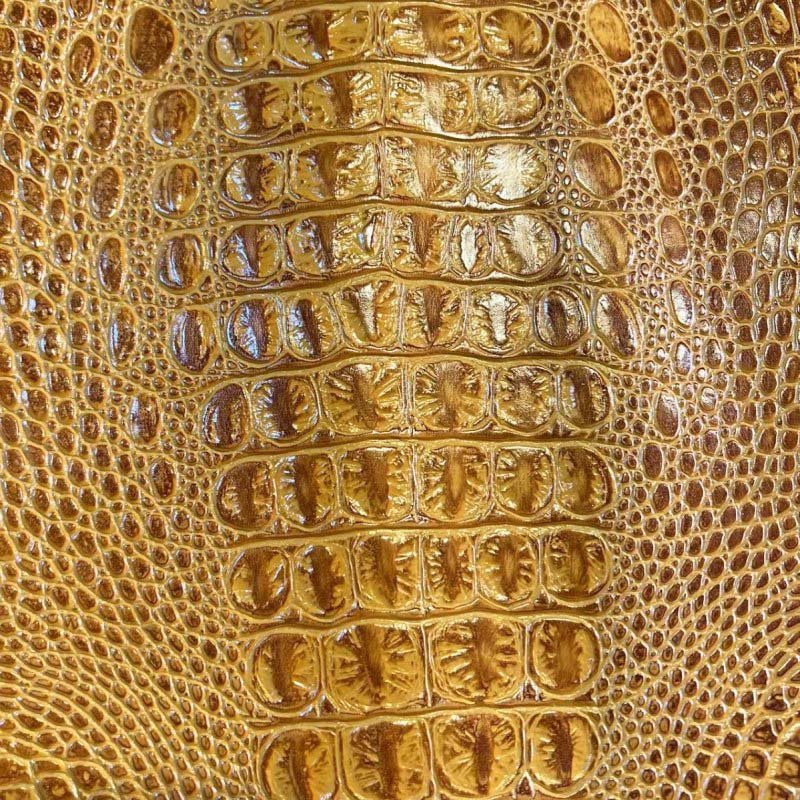

Crocodile Leather Bag

Crocodile leather bags epitomize ultimate luxury with their iconic scale patterns, offering unmatched durability and a prestigious texture that commands attention.

Recycled Leather Bag

Recycled leather bags give new life to discarded materials, offering an eco-conscious choice with the look and feel of genuine leather while reducing environmental impact.

Frequently Asked Questions

To choose the right material for a leather bag or wallet project, you should consider the target market, price range, product function, and branding requirements.

Premium or luxury products typically use full-grain or vegetable-tanned leather for durability and aging performance, while mid-range or volume-driven projects often select top-grain or chrome-tanned leather for cost efficiency and color consistency. Material thickness, softness, and compatibility with logo embossing or hardware should also be evaluated to ensure stable sampling and mass production.

Full-grain leather is the highest-quality leather, made from the top layer of the hide with the natural grain intact, offering maximum durability and natural aging.

Top-grain leather is lightly corrected to remove surface imperfections, providing a smoother, more uniform appearance with good durability at a more controlled cost.

Genuine leather refers to processed leather made from lower layers of the hide; it is more affordable but generally offers lower durability and aging performance compared to full-grain and top-grain leather.

Premium or luxury leather goods are best made with full-grain leather and vegetable-tanned leather, as they offer superior durability, natural texture, and refined aging over time.

These materials are ideal for high-end handbags and wallets because they support clean construction, precise stitching, and long-lasting branding details, while reinforcing a luxury brand’s quality positioning.

Cost-sensitive or entry-level leather products typically use top-grain leather, split leather, or coated leather, which offer stable quality at a more competitive cost.

These materials are well suited for bulk production, provide consistent color and finish, and allow brands to balance pricing, durability, and market accessibility without compromising basic functionality.

Material selection directly affects the durability and lifespan of leather products by determining strength, wear resistance, and aging performance.

Higher-quality leathers such as full-grain or vegetable-tanned leather offer better fiber density and long-term durability, while lower-grade or coated leathers typically have a shorter lifespan. Proper lining and reinforcement materials also play a key role in maintaining structure and extending product life.

For handbags, full-grain or top-grain leather is preferred for durability, structure, and premium appearance.

For wallets, vegetable-tanned or full-grain leather is commonly used due to its firmness, clean edges, and long-term aging.

For small leather goods, top-grain, split leather, or chrome-tanned leather are often selected to balance flexibility, cost, and consistent bulk production.

Structured bags are best made with firm full-grain or top-grain leather, combined with reinforcement materials to maintain shape and sharp lines.

Soft or slouchy designs typically use softer chrome-tanned or tumbled leather, which provides flexibility, drape, and a relaxed feel while remaining suitable for mass production.

For high-frequency daily use products, full-grain leather and high-quality top-grain leather work best due to their strong fiber structure and abrasion resistance.

These leather types maintain appearance over time, resist cracking, and perform reliably under repeated handling, making them ideal for everyday handbags and wallets.

Material thickness directly affects a bag’s structure, weight, and hand feel.

Thicker leather provides better shape retention and durability but increases weight, making it suitable for structured bags. Thinner leather offers a lighter, softer feel and more flexibility, which works well for soft or slouchy designs.

Yes. MOQs can vary depending on the selected material, as leather availability, dyeing requirements, and sourcing methods differ by type.

Standard or commonly stocked materials usually allow lower MOQs, while custom colors, specialty leathers, or imported materials may require higher minimum order quantities to ensure production efficiency and material consistency.

Imported leather generally costs more than domestic leather due to higher raw material prices, transportation, and longer supply chains.

Domestic leather options offer better cost control and shorter lead times, while imported leathers are often selected for premium texture, specific finishes, or luxury positioning.

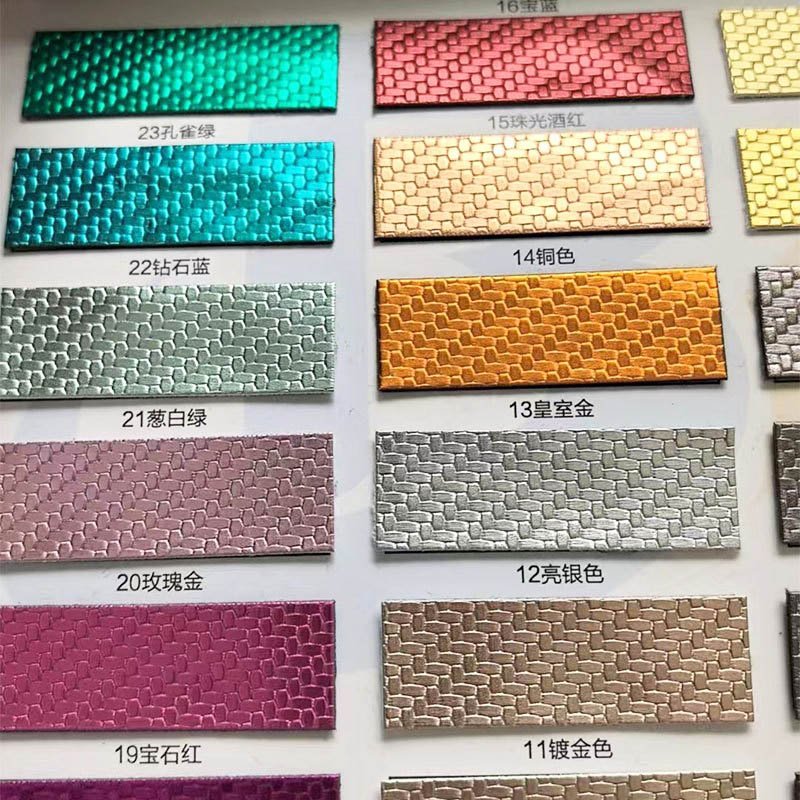

Yes. Materials can be customized in color, texture, and finish to meet private label requirements.

Common options include custom dye colors, grain embossing, surface treatments, and finish adjustments, subject to material availability, MOQ, and production feasibility.

Yes. Different materials can be mixed in one product design, such as leather combined with fabric, canvas, or microfiber.

Material mixing is commonly used to optimize cost, weight, functionality, and visual contrast, while maintaining durability and suitability for mass production.

Eco-friendly options for leather goods manufacturing include vegetable-tanned leather, LWG-certified leather, and recycled or low-impact lining materials.

These materials help reduce environmental impact while meeting durability and quality requirements for responsible B2B production.

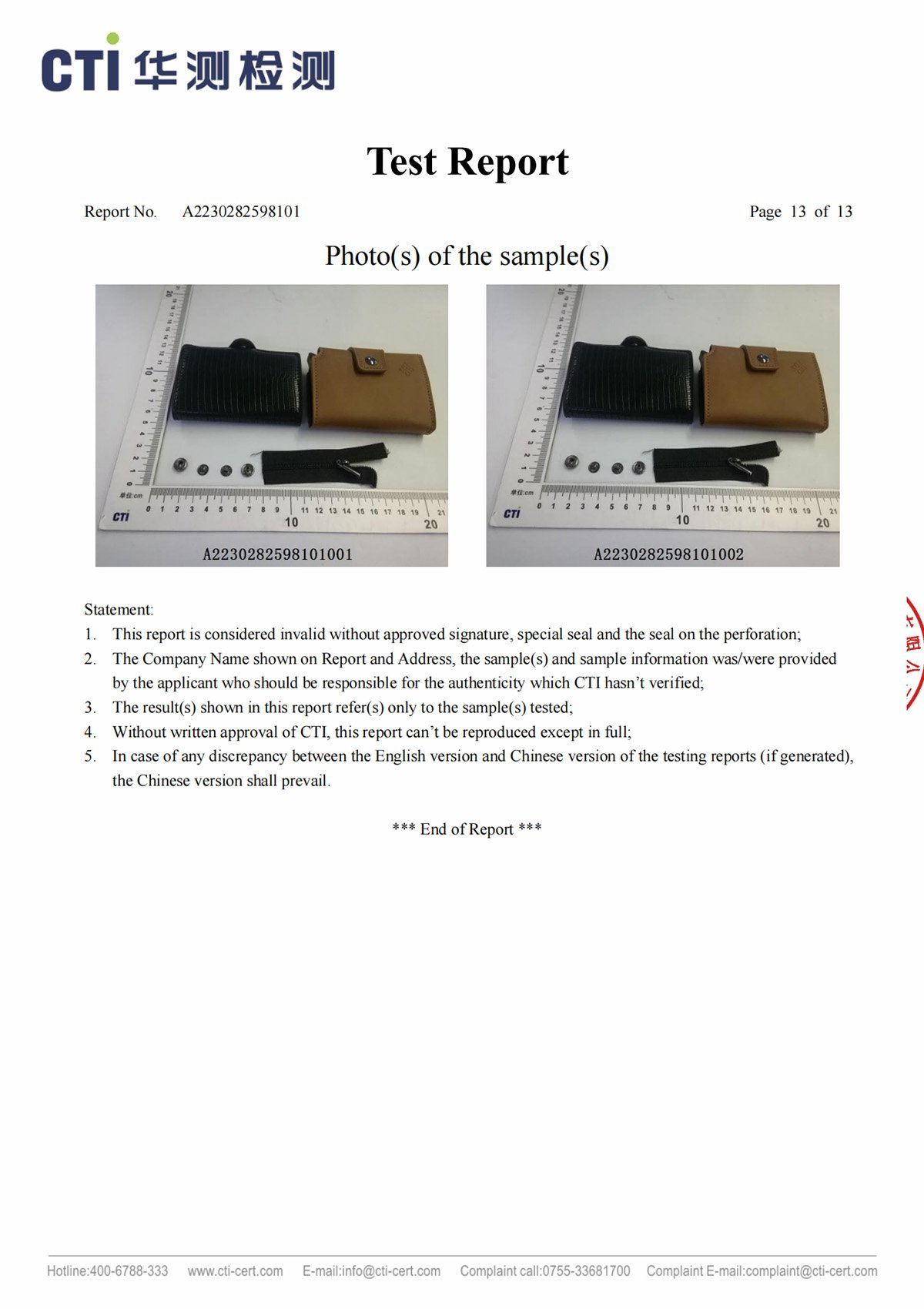

Compliance with standards such as REACH and Prop 65 depends on the specific material, tanning process, dyes, and finishes used.

Most commonly used leathers, linings, and hardware can meet international compliance requirements when sourced and processed according to certified standards and verified testing procedures.

Yes. Material selection can affect both sample lead time and production timeline.

Standard or in-stock materials usually allow faster sampling and production, while custom colors, specialty leathers, or imported materials may require additional sourcing time before manufacturing can begin.

Material color and texture can be highly consistent in bulk production when standardized materials and controlled dye lots are used.

Natural leather may show slight variations between batches, but proper material selection, color matching, and quality control help ensure overall visual consistency across large orders.

When selecting new or uncommon materials, buyers should consider risks related to cost stability, supply consistency, color variation, and mass production feasibility.

Unproven materials may also affect sampling timelines, MOQ requirements, and long-term reorder consistency, so testing and evaluation before bulk production is recommended.

Elevate Your Brand with Mherder

Take your brand to the next level with Mherder, Guangzhou’s trusted leader in premium leather bag manufacturing. Perfect for importers, brand owners, Amazon sellers, retailers, and wholesalers, we provide free designs and customization services to bring your vision to life. With a catalog of over 5000 styles, we offer everything from leather bags to accessories, all crafted with exceptional quality.

Download your free market report and competitive analysis now to gain insights and stay ahead in the industry!

Customer Testimonials

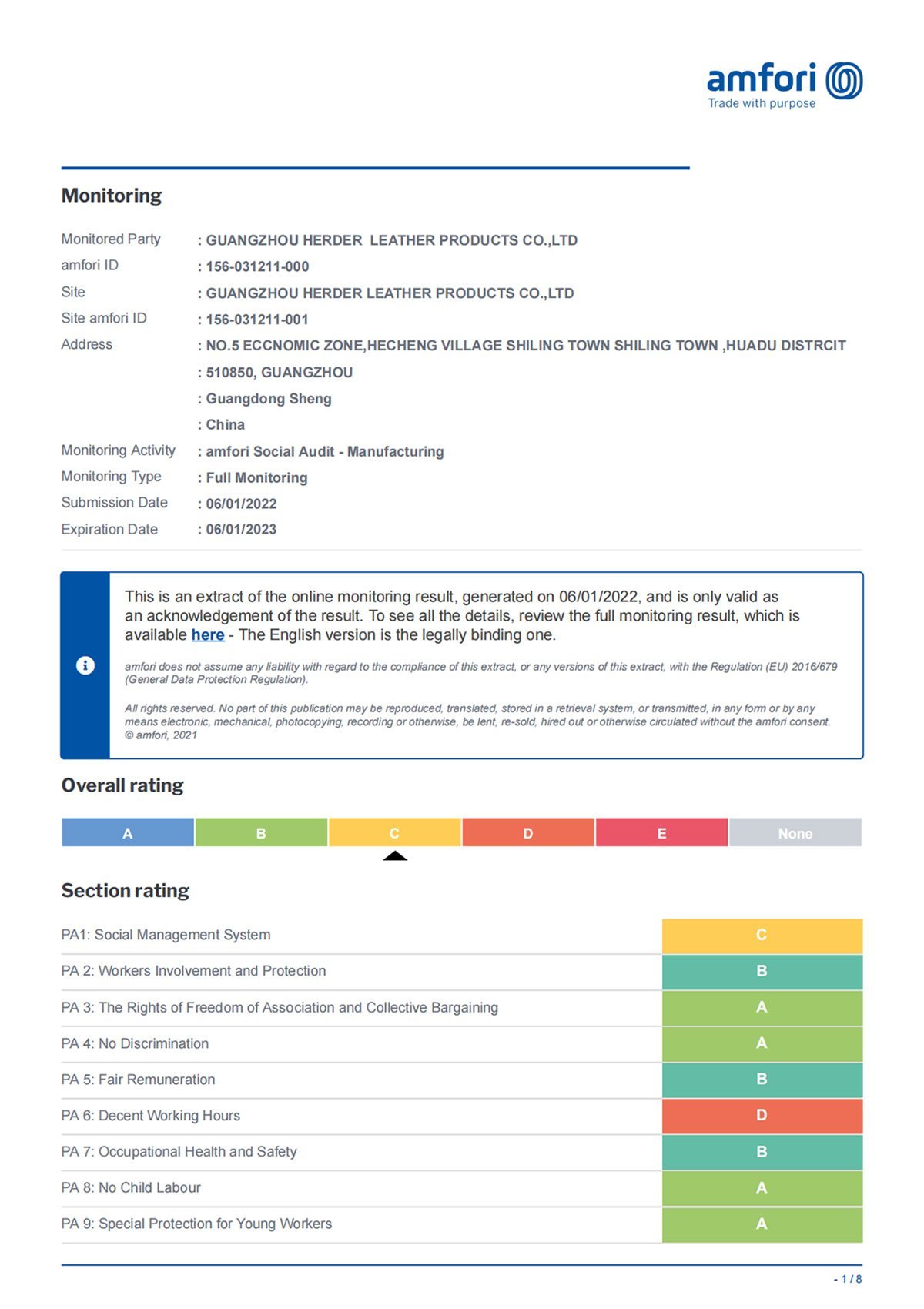

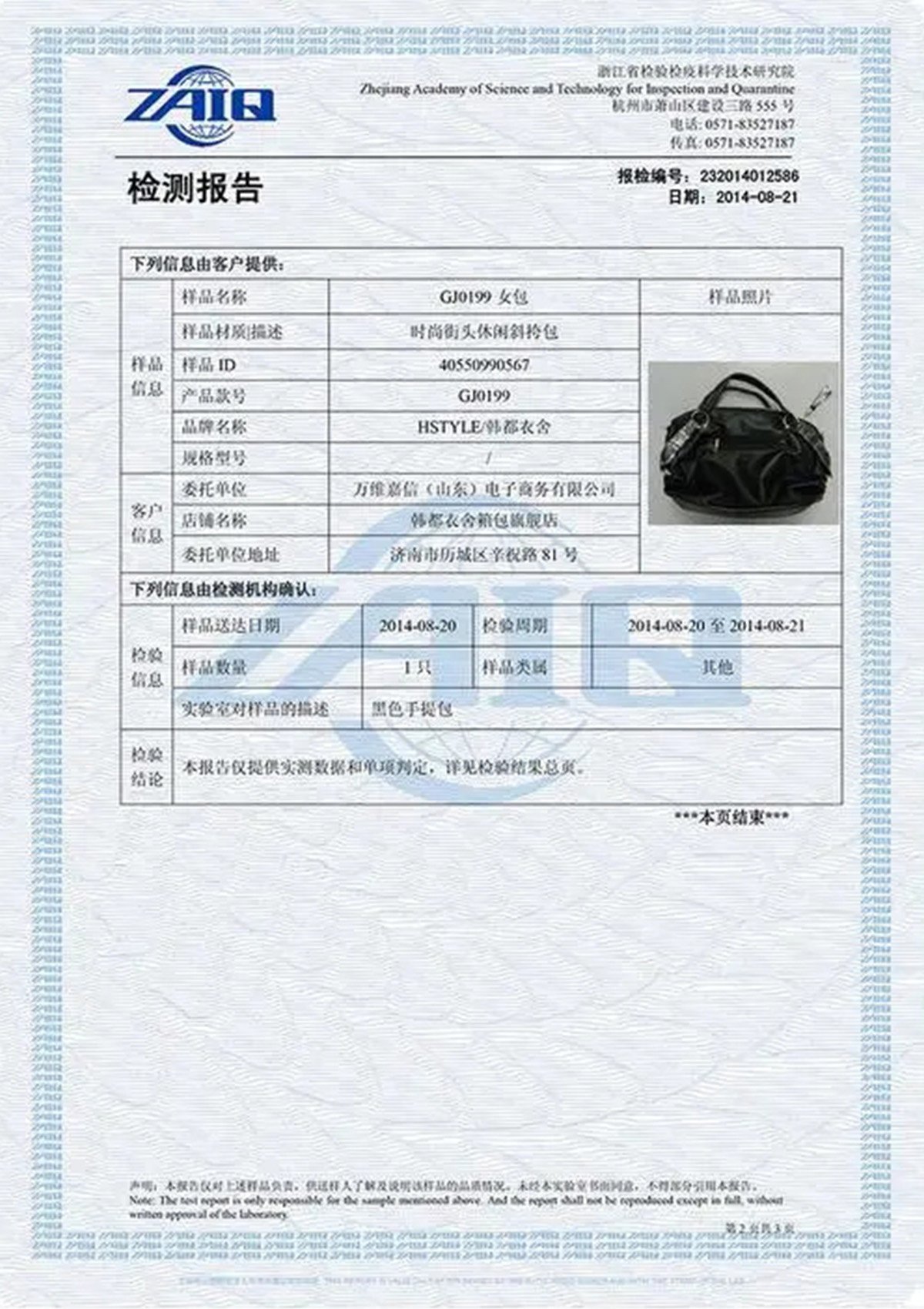

Our Cetificate/Inspection Report

Recent Related Articles

How to Start Your Project

Welcome to our premier leather goods manufacturing company based in Guangzhou. We take great pride in specializing in the production of top-quality leather goods, meticulously crafted with premium genuine leather materials. Over the past 18 years, we’ve honed our expertise in providing customized leather goods solutions, showcasing our dedication to fine craftsmanship and ensuring utmost customer satisfaction. How can we assist you today?