Leather Garment Bags: OEM & Wholesale Travel Solutions

Leather garment bags are developed for clothing brands, travel brands, uniform suppliers, and retail chains that require consistent garment protection and professional presentation across bulk distribution programs. These products are engineered to support long-distance transportation, repeat handling, and export-oriented supply chains.

Designed to securely carry suits and tailored garments during travel, leather garment bags are suitable for wholesale assortments and long-term sourcing plans. Convertible formats such as leather garment duffel bags combine hanging garment storage with compact luggage functionality, making them suitable for business travel collections and coordinated luggage lines.

Constructed with full-grain leather, reinforced stitching, and heavy-duty zippers, these bags are built to maintain structure and appearance under frequent use. Product specifications are controlled to ensure consistency across private-label and wholesale programs, supporting repeat orders without variation.

As a professional leather garment bags manufacturer in China, Guangzhou Herder Leather has been supplying international B2B buyers since 2006 from its Guangzhou-based facility. The factory operates OEM and ODM programs with in-house development, controlled leather sourcing, and scalable mass production to support long-term sourcing partnerships.

From structural development to bulk production execution, dedicated teams ensure stable quality across repeat orders for brands, importers, and large-scale online sellers. With extensive experience in leather garment duffel bags and convertible garment bag structures, the factory supports cohesive luggage and garment protection ranges built to export-ready quality standards.

Leather Garment Bags Product Specifications Section

Leather garment bags are available in foldable, tri-fold, suit-length, and travel-length structures to support different garment transport requirements, including standard garment bags and 2-in-1 garment duffel formats. Interior layouts are designed to secure suits and clothing during movement, helping reduce shifting and creasing in bulk transportation and export handling.

Zippers, hooks, handles, and shoulder straps are reinforced for repeated use in men’s leather garment bags and convertible garment bag designs. Hardware and construction specifications are fixed once approved to ensure consistency across repeat orders.

Private-label branding options include logo embossing or debossing, custom zipper pulls, labels, and export-ready packaging formats suitable for wholesale and distribution programs. All products are manufactured in compliance with international export and packaging standards to support long-term bulk supply.

Types of Premium Leather Garment Bags We Produce

One-Stop Solutions for Custom Leather Garment Bags

Leather Garment Bags – Product Selling Points

- Full-grain leather is selected for long service life and structural stability, supporting repeat orders and reducing after-sales issues in wholesale and distribution channels.

- Interior structures are engineered to secure garments during travel and bulk transportation, helping minimize creasing compared to soft luggage or standard suit bags.

- Convertible designs function as both garment bags and travel bags, allowing brands and retailers to offer versatile products suitable for business travel collections.

- Private-label customization includes logo embossing or debossing, custom hardware, and branding elements aligned with premium luggage positioning.

- Approved specifications are locked for production, ensuring every unit matches the confirmed sample and remains consistent across repeat orders and export shipments.

Factory Advantages – Leather Garment Bags Manufacturer in China

Leather garment bags are produced under a controlled manufacturing system designed for repeat orders and long-term B2B sourcing programs.

- In-house development teams support multiple garment bag structures, including standard garment bags, garment duffel bags, and 2-in-1 convertible formats, ensuring designs can be executed consistently at scale.

- Leather materials are inspected and approved by specification, with grain, color, and thickness standards locked to maintain consistency across bulk production runs.

- Structural engineering is applied to folding areas, load-bearing points, and stress zones to ensure durability in convertible and travel-oriented garment bag designs.

- Sewing, edge finishing, and hardware attachment processes are monitored through defined quality control checkpoints to reduce defect rates in bulk orders

Premium Leather Materials You Can Choose for Your leather products

Confidentiality & IP Protection

We will sign a confidentiality agreement to protect your drawings, and we are also happy to protect your ideas by signing a non-disclosure agreement (NDA).

- Confidentiality Agreement Ready: We are prepared to sign a formal Confidentiality Agreement before receiving or reviewing any of your design files or technical documents.

- NDA Available Upon Request: To further protect your intellectual property, we are happy to sign a Non-Disclosure Agreement (NDA) provided by yo u, or we can offer our standard NDA template.

- Secure File Handling: All drawings, measurements, and brand assets are stored securely and treated with the utmost confidentiality throughout the entire development and production process.

- Respect for Your Brand’s IP: We do not share, reuse, or replicate your designs in any way. Your ideas remain exclusively yours.

Wait! Don't Miss Out!

Still not finding what you’re looking for? Contact our consultants for more available products.

FAQ

For bulk and private-label orders, branding options include logo embossing or debossing on exterior leather panels, custom zipper pulls, branded labels, and bespoke lining patterns.

Branding specifications are confirmed at the sampling stage and locked for production to ensure consistency across all units in wholesale and distribution programs.

Leather selection is aligned with brand positioning. Full-grain cowhide is recommended for premium and boutique programs where long service life, structure retention, and high-end positioning are required.

For mainstream wholesale and luggage programs, top-grain leather is commonly used, offering a balanced combination of durability, appearance consistency, and cost control. Leather specifications are confirmed during sampling to ensure suitability for long-term bulk production.

For repeat B2B orders, production lead times are based on confirmed specifications and material availability. Custom leather garment bag orders require approximately 30–40 days after sample approval.

In-stock leather garment bag orders are typically fulfilled within 5–10 days, subject to order quantity and final packaging requirements. Lead times are managed to support seasonal planning and repeat wholesale programs.

Export packaging is selected based on the structural characteristics of the bag. For foldable leather garment bag designs, products can be folded to reduce shipping volume. For structured or non-foldable styles, bags are stuffed with protective paper to maintain shape during transportation.

All units are packed in polybags and export cartons to protect against moisture and pressure during international shipping, ensuring the products arrive ready for wholesale or retail distribution.

Leather garment bags are suitable for B2B buyers operating in premium travel, apparel, and corporate distribution channels.

Typical buyer profiles include luxury travel brands, high-end menswear retailers, uniform suppliers, and corporate gifting distributors.

Convertible garment duffel formats are commonly selected for business travel collections, while traditional suit-length garment bags are preferred for formal apparel and retail programs.

These products are designed to support wholesale, private-label, and repeat sourcing models.

Consistency is ensured through locked production specifications for each private-label program. Approved samples are documented as internal production references, including leather grain, color, thickness, hardware, and construction details. For repeat orders, production is executed strictly against these records to maintain alignment with the previously approved sample across all bulk shipments.

Quality inspections are conducted at defined production stages and prior to shipment. Inspection points include leather surface condition, stitching quality, zipper performance, and load-bearing areas such as handles and straps.

Products are checked to ensure structural stability and suitability for carrying garments during transportation. These procedures are applied consistently across bulk orders to reduce defect rates and maintain stable quality standards.

Shipping formats are determined by the structural design of the bag. Foldable and soft-sided leather garment bag styles, such as convertible garment duffel bags, can be folded to optimize container space.

Structured or full-length garment bags that cannot be folded are shipped flat to prevent creasing and deformation. Shipping configurations are selected to balance space efficiency with product protection, ensuring the bags arrive suitable for wholesale or retail distribution.

Customer Testimonials

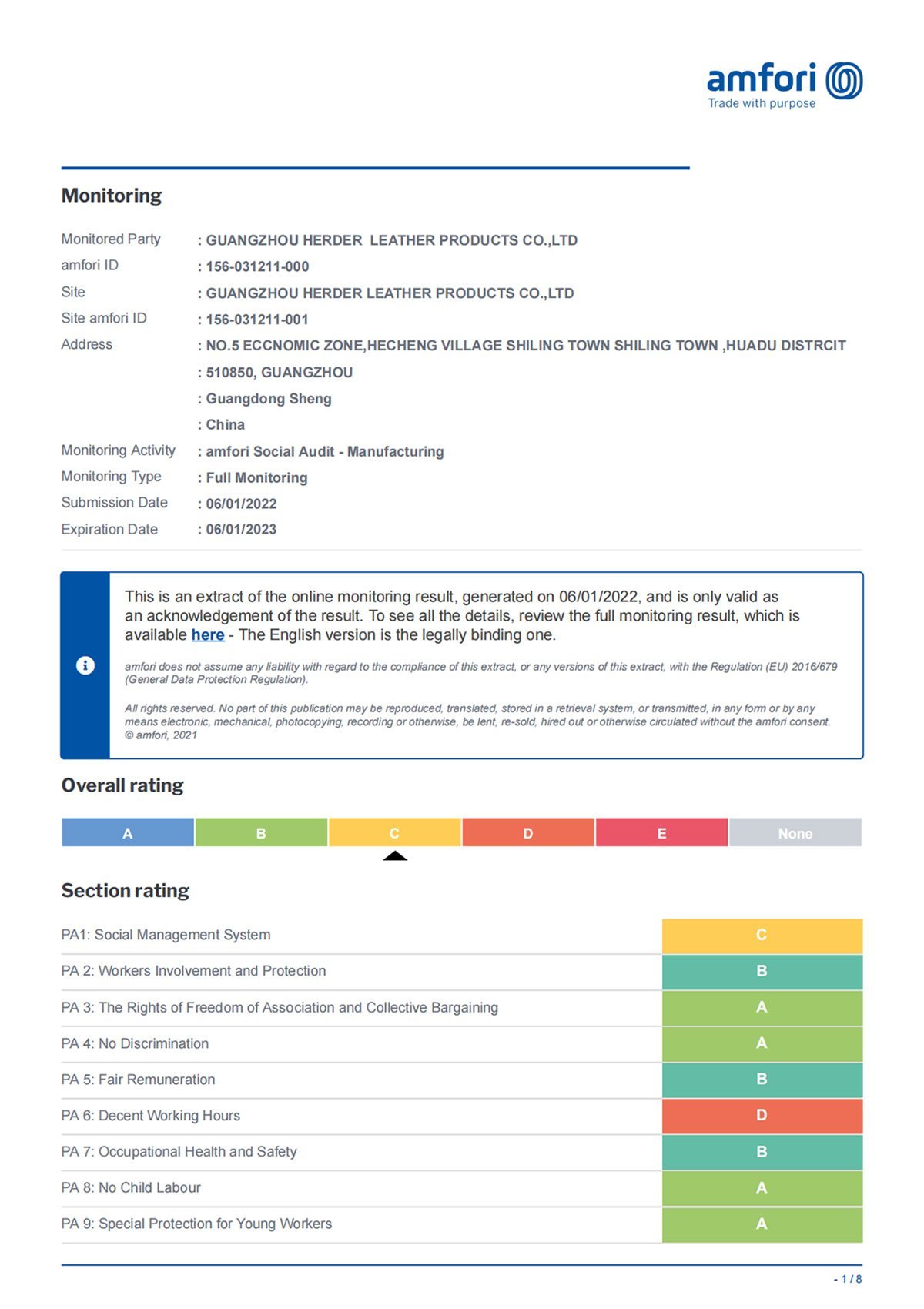

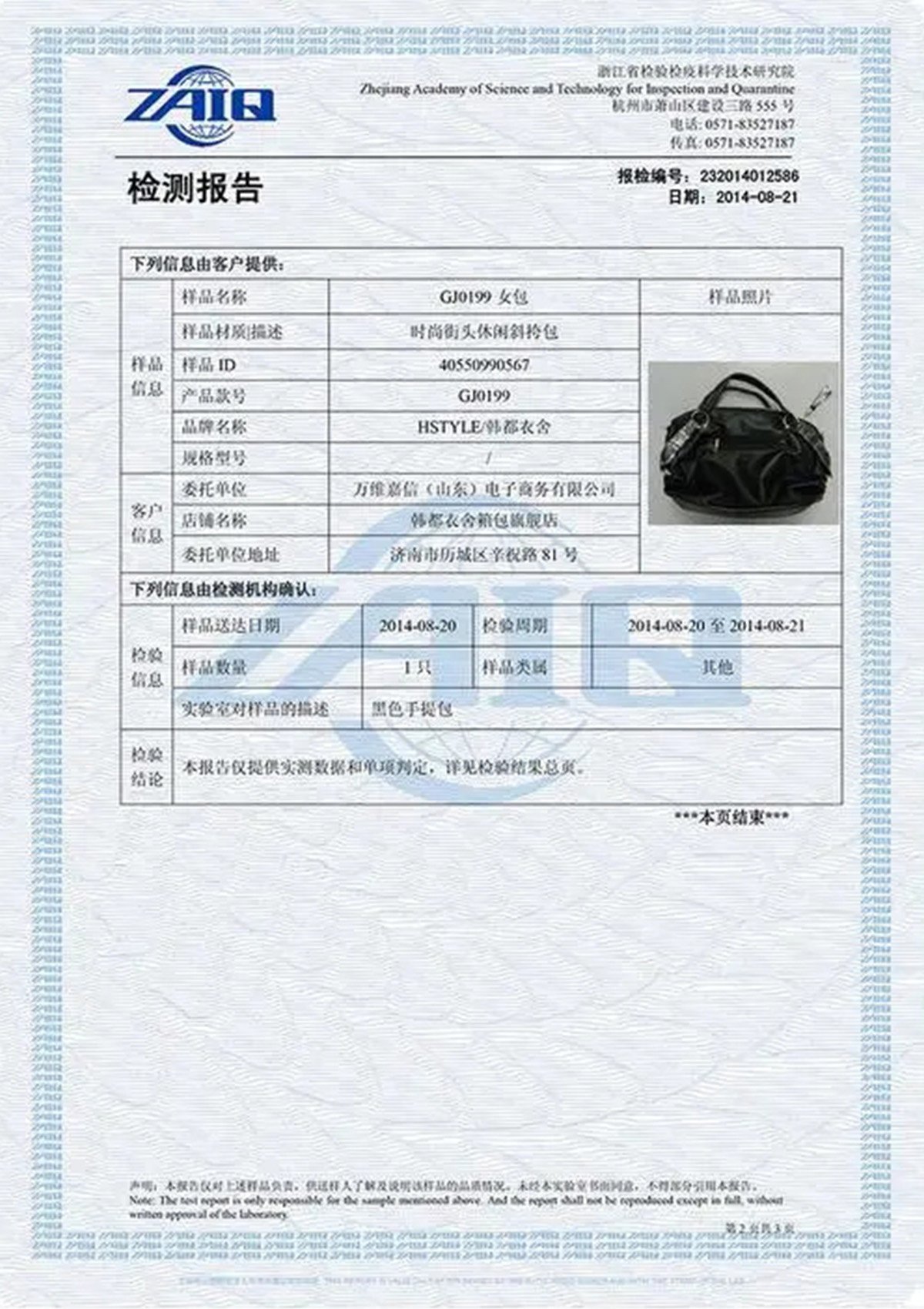

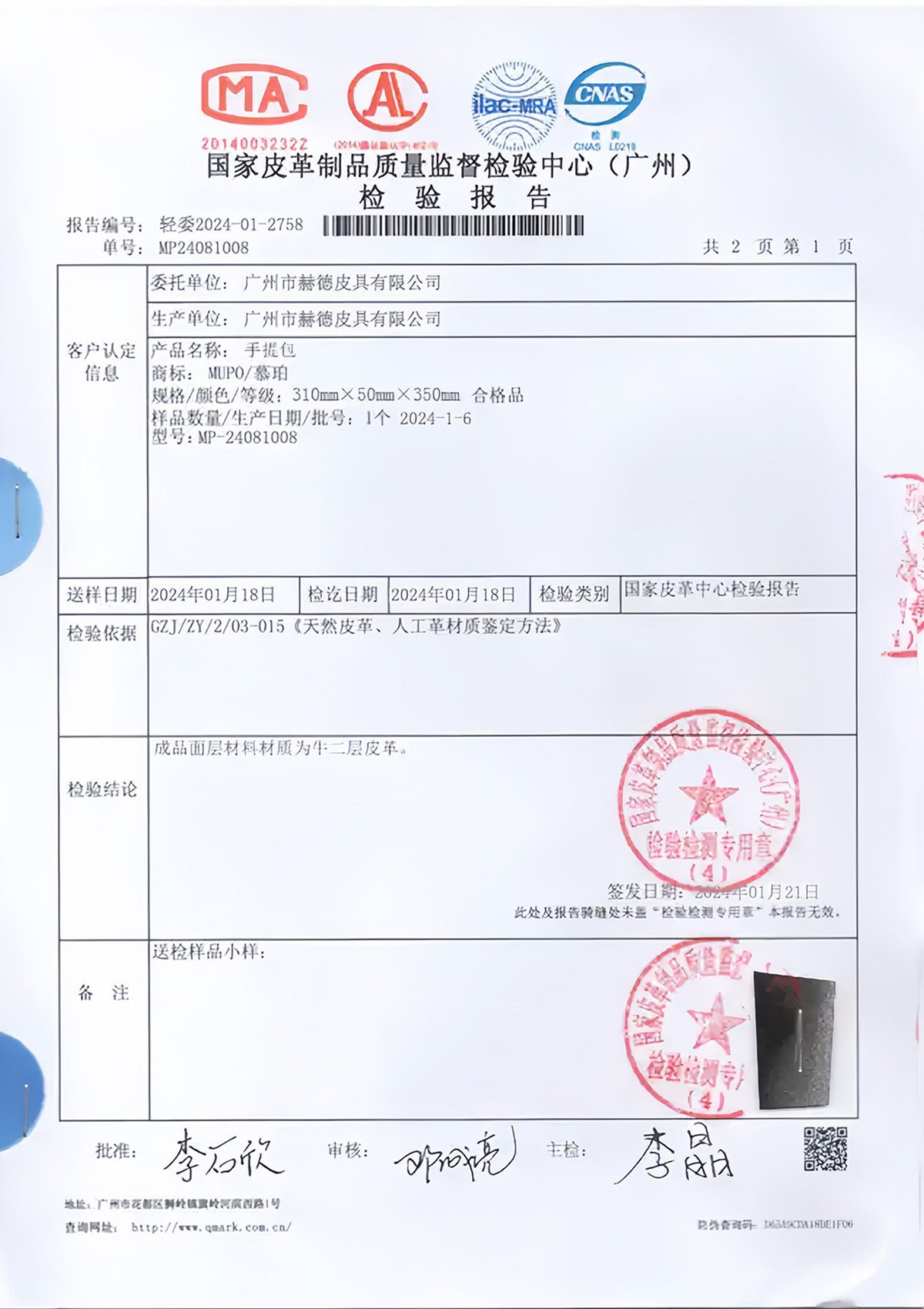

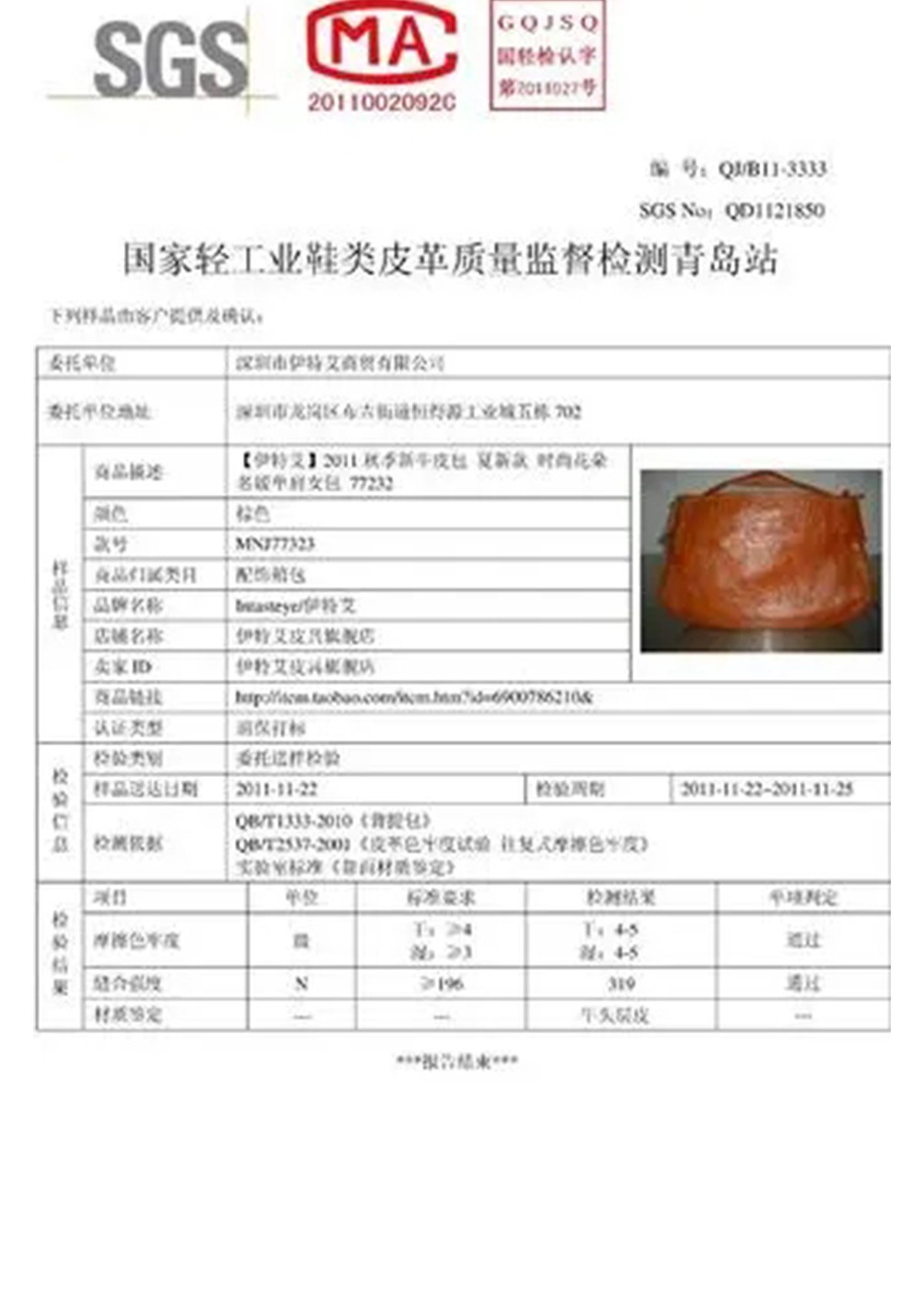

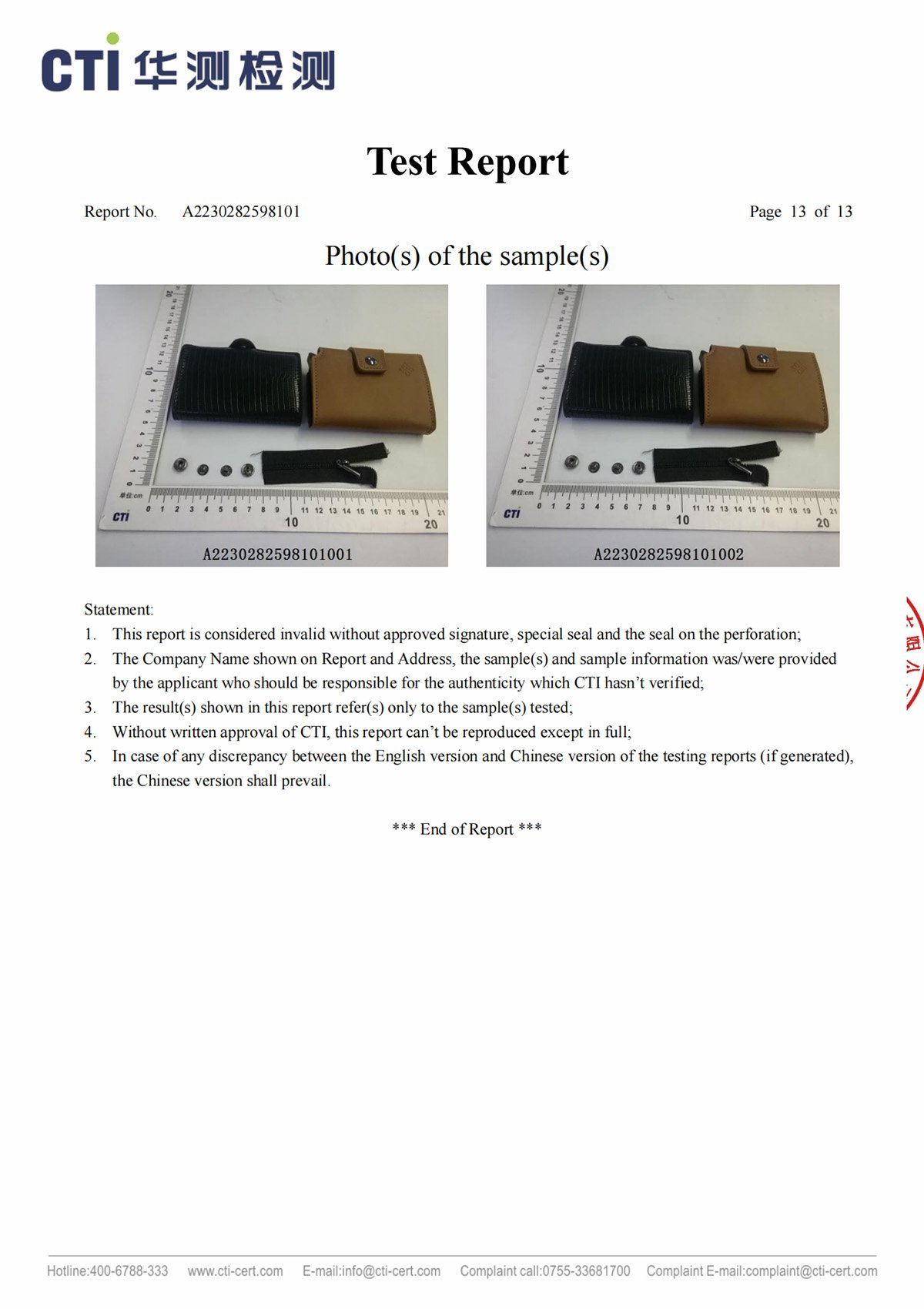

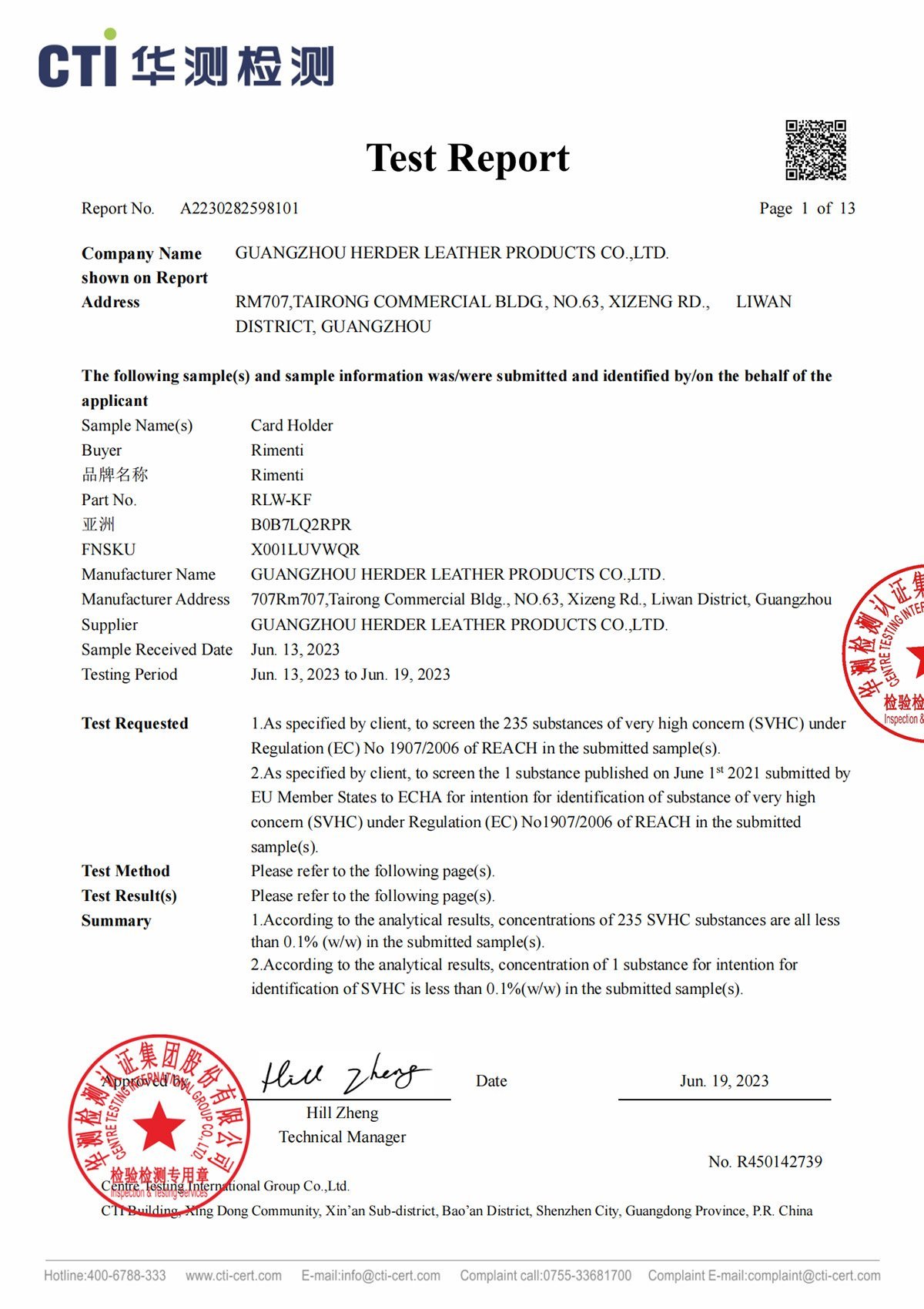

Our Cetificate/Inspection Report

Recent Related Articles

Welcome to our premier leather goods manufacturing company based in Guangzhou. We take great pride in specializing in the production of top-quality leather goods, meticulously crafted with premium genuine leather materials. Over the past 18 years, we’ve honed our expertise in providing customized leather goods solutions, showcasing our dedication to fine craftsmanship and ensuring utmost customer satisfaction. How can we assist you today?