Leather Bag Categories for OEM & Private Label

Key Features and Advantages

Why Choose Mherder for Leather Bags in China

• 18+ years OEM/ODM leather bag manufacturing experience

• 100+ new developments monthly (new styles, revisions, prototypes)

• 5,000+ ready-to-ship styles to choose from (availability applies)

• Typical MOQ: 100–300 pcs per style/color (varies by material & construction)

• Sample lead time: 5–14 days; bulk production: 25–40 days after sample approval

• 100+ customization options: materials, hardware, logo, packaging

• Catalogs available by category for faster style selection (PDF)

• Sustainable options: recycled leather and selected plant-based alternatives

• Shipping support: courier/air/sea; DDP available for eligible destinations

Custom Leather Bags Manufacturer for Brands & Wholesalers

- Customized Leather Bag Factory

We manufacture to buyer-approved specifications and keep reference samples for consistent repeat production. - Sampling & Pre-Production

We review structure, materials, and cost targets before sampling, then confirm details with a pre-production sample and spec sheet. - Branding & Packaging

Branding options include emboss/deboss, metal logo, laser engraving, woven labels, and hangtags. Gift boxes, dust bags, and barcode/label packing can be arranged. - Quality Control Workflow

QC runs from material inspection to final inspection, with checkpoints on leather thickness tolerance, hardware plating durability, and reinforcement at load-bearing points.

Build Your Leather Bag to Buyer Specs

We develop to your tech pack or samples, with customization across materials, hardware, structure, and layout. Branding and packaging options are available, with buyer-approved specs saved for repeat production.

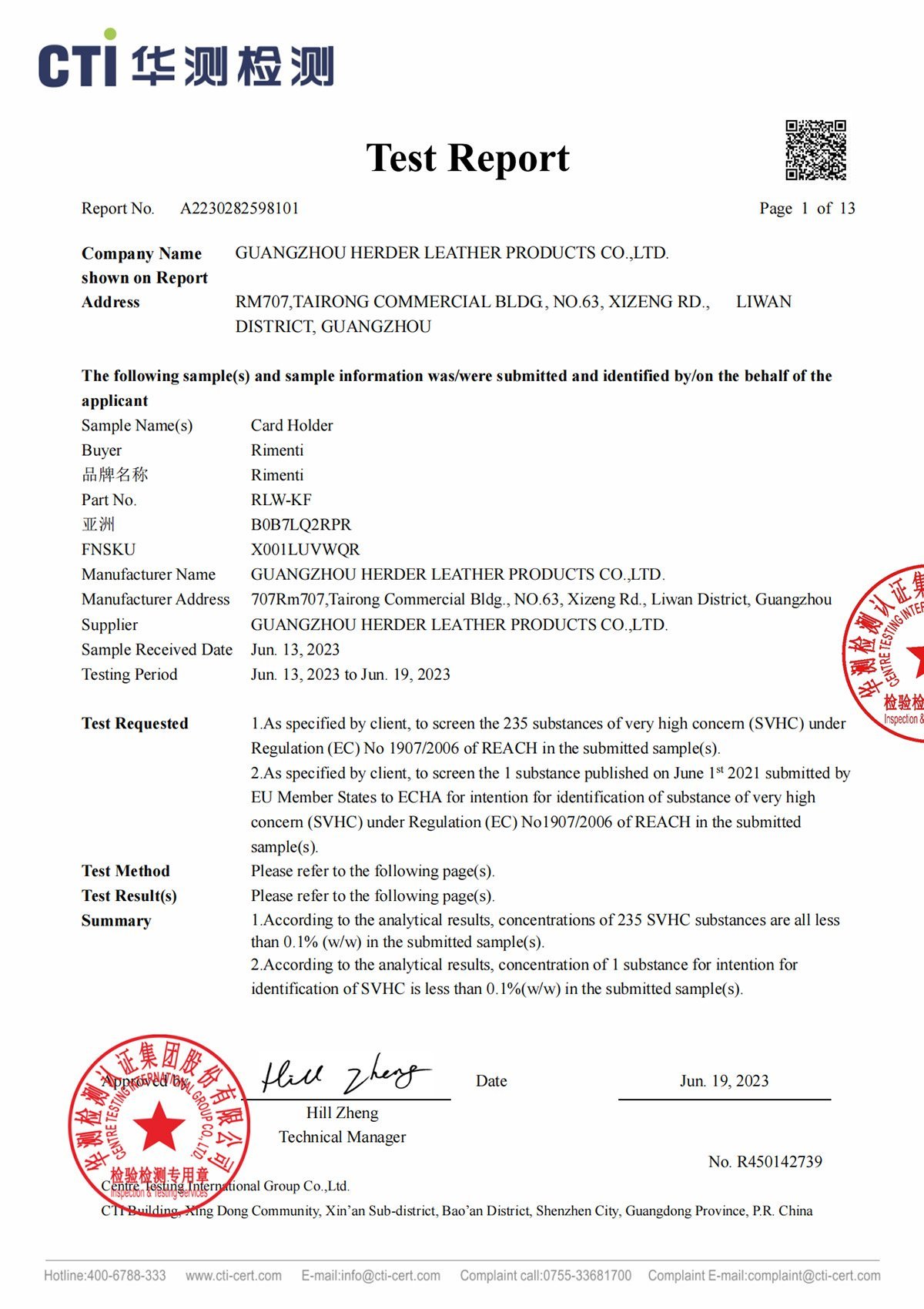

Materials & Compliance

We source leather and trims to buyer-approved specifications. Third-party testing can be supported through recognized labs such as SGS / Intertek (scope depends on material and product category).

Sustainable Material Options for Your Program

We support sustainable material programs using recycled leather and selected plant-based alternatives. Documentation and third-party testing can be supported when required (scope depends on material and product category).

Why Choose Mherder China for

Custom Leather Bags

One-Stop OEM/ODM Solutions for Custom Leather Bags

Professional Leather Bag Manufacturer in China

We offer 5,000+ in-stock bag designs for fast wholesale programs.

MOQ starts from 20 pcs per style (in-stock styles; mixed styles/colors available), helping you reduce inventory risk.

Ready-to-ship orders can be dispatched in 5–7 days after payment (subject to stock and destination).

Wait! Don't Miss Out!

Still not finding what you’re looking for? Contact our consultants for more available products.

Leather Material Selection

Discover your perfect leather bag match – from top grain cow leather to soft lambskin, customize or wholesale bags that define your style. Whatever you need, we source the perfect leather for your order, tailored to your unique requirements.

Full-Grain Cow Leather Bags

Premium full-grain cowhide leather bags—naturally durable with visible grain marks, developing richer patina over time for enduring elegance.

Top-Grain Cow Leather Bags

Vegetable Tanned Cow Leather Bag

Vegetable-tanned cow leather bags age beautifully, developing a unique patina over time while being eco-friendly and free from harmful chemicals.

Distressed Cow Leather Bag

Distressed cow leather bags showcase rugged charm with intentionally weathered textures—pre-aged for vintage character while maintaining structural durability.

Split Leather Bag

LambSkin Bag

Lambskin bags embody luxurious softness with their featherlight suppleness, offering a buttery-smooth texture that drapes elegantly for effortless sophistication.

Horse Leather Bag

Horse leather bags combine exceptional durability with a distinctive grain pattern, offering a unique blend of strength and lightweight flexibility for enduring style.

Suede/Nubuck leather Bags

Experience the luxurious texture of suede/nubuck leather – a soft, velvety finish that adds refined elegance to any leather accessory or leather bags.

Crocodile Leather Bag

Crocodile leather bags epitomize ultimate luxury with their iconic scale patterns, offering unmatched durability and a prestigious texture that commands attention.

Recycled Leather Bag

Recycled leather bags give new life to discarded materials, offering an eco-conscious choice with the look and feel of genuine leather while reducing environmental impact.

Frequently Asked Questions

In legal commercial markets, the most expensive leathers are typically exotic leathers such as alligator/crocodile and high-grade ostrich, because of limited supply, strict grading, and high defect rejection rates. Premium full-grain calfskin and high-quality vegetable-tanned leathers can also be expensive due to tighter selection standards and longer tanning cycles. For B2B buyers, the “most expensive” leather is less important than selecting a leather that matches your target retail price, durability requirement, and repeat-order consistency.

A practical B2B grading framework is:

- Full-grain leather: Natural grain surface, strongest fiber structure, best aging, highest cost.

- Top-grain leather: Sanded/refined surface for more uniform appearance; strong and widely used for retail-ready bags.

- Corrected-grain leather: Surface is more heavily finished/embossed to hide imperfections; more consistent look, usually more cost-controlled.

- Split leather (including suede): Lower layer of hide; softer handfeel but lower tear strength than full/top-grain, often used with finishes or as suede/nubuck.

For wholesale/OEM programs, choose based on wear level, desired appearance, and acceptable cost band—not just the label.

Lambskin (often nappa lambskin) is commonly one of the softest leathers used for bags. It delivers a smooth, premium handfeel and drape, which is why it’s popular in fashion handbags. The trade-off is lower abrasion resistance compared with cowhide, so it suits styles that prioritize softness and luxury touch over heavy-duty daily wear. For B2B development, confirm the usage scenario and add reinforcement at stress points if lambskin is selected.

Common causes of leather bag damage include:

- Water and high humidity: can cause stains, deformation, and mold.

- Heat and sunlight: can dry leather, fade color, and lead to cracking over time.

- Dirt, oil, and cosmetics: build up and can weaken finishes if not cleaned properly.

- Abrasion and sharp objects: cause scratches, scuffs, and cuts.

- Incorrect cleaning chemicals: alcohol, strong detergents, and disinfectants can strip oils and damage finishes.

- Improper storage: compression and damp storage can deform structure and create mold.

For B2B buyers, define a care label and packaging/storage standard to reduce after-sales issu

Use a production-focused checklist:

- Leather selection: consistent grade, thickness, and temper; stable color between batches.

- Pattern and structure: clean alignment, balanced panel symmetry, reinforced load-bearing areas (handles, strap anchors, base).

- Stitching: even stitch length, correct thread size, reinforced backstitch at stress points, no skipped stitches.

- Edge finishing: smooth edge painting/edge finishing with proper base coat and top coat; no cracks or sticky edges.

- Hardware: smooth zipper performance, consistent plating color, no sharp burrs, secure attachment.

- Lining and bonding: clean glue lines, no bubbling, neat seam binding, stable pocket construction.

For OEM/wholesale, always lock an approved sample and written spec as the reference for repeat orders.

With proper use and care, full-grain and good top-grain leather bags can last 5–10+ years, especially when structure and stress points are reinforced. Corrected-grain and split leather typically have a shorter service life, often around 2–5 years depending on usage and finish type. Lifespan is mainly affected by frequency of use, abrasion exposure, moisture/heat, and storage method. For B2B programs, choosing the right leather plus correct reinforcement is the key to reducing returns and improving repeat sales.

- Remove dust: wipe with a soft, dry cloth.

- Spot clean: use a dedicated leather cleaner, or a slightly damp cloth with mild soap (test on a hidden area first).

- Dry immediately: wipe with a clean, dry cloth to remove moisture.

- Air dry: keep in a ventilated area away from heat and direct sunlight.

Important: Do not soak the bag, do not use alcohol/disinfectant wipes, and do not use a hair dryer. For suede/nubuck, use a suede brush and suede-safe protector. For premium or delicate leathers, professional cleaning is recommended.

“Sustainable leather” usually means lower environmental impact and better traceability across tanning and supply chain. Common options include:

- Vegetable-tanned leather: uses plant-based tannins; durable and biodegradable, but typically higher cost and longer lead time.

- Recycled leather: made from regenerated leather fibers; reduces waste and can be cost-effective, but strength and handfeel are not the same as full-grain.

- Bio-based leather alternatives (non-leather materials): made from plant-based inputs; sustainability depends on composition, coatings, and durability, and usually comes with higher MOQ.

For B2B buyers, the best choice depends on your sustainability claim requirements, target price, performance expectations, and available certifications.

MOQ depends on leather type, construction complexity, and hardware customization.

For standard leather bag styles, MOQ typically starts from 100–300 pcs per style per color.

For special materials, custom hardware, or complex structures, MOQ may be higher.

For in-stock programs, lower MOQ options may be available depending on current inventory.

Typical timeline includes 7–15 days for sampling and 30–45 days for bulk production after sample approval and deposit.

Lead time may vary based on order quantity, leather availability, and customization level.

During peak seasons or before major holidays, production time may extend.

Yes. We can develop based on your reference sample, tech pack, or physical prototype.

We analyze leather type, thickness, construction method, hardware specs, and reinforcement structure to match performance and appearance.

Approved samples are used as production standards for repeat orders.

Quality is controlled through material inspection, in-line production checks, and final inspection before packing.

Approved samples and production specifications are locked before bulk production to maintain consistency between batches.

Critical areas such as stitching density, leather thickness tolerance, and hardware plating are monitored.

Yes. We support private label production and can sign NDA agreements if required.

Client designs, molds, and custom hardware developments are kept confidential and used only for authorized production.

Top-grain cow leather is commonly used for large-volume retail programs because it balances durability, appearance consistency, and cost control.

Full-grain leather is typically used for higher-end positioning, while corrected-grain leather may be used for strict cost-target programs.

We control color consistency by locking a physical color standard (approved sample or signed swatch) and using it as the reference for every repeat order. For each batch, we confirm the leather tannery, dye lot, finish type (aniline / semi-aniline / pigmented), and target gloss level to reduce variation. We also run a pre-production color check under controlled lighting and compare panels against the master standard before cutting. For long-term programs, we recommend reserving the same leather source and documenting tolerances to keep repeat orders stable.

We match hardware to leather tone by selecting plating color and finish (e.g., light gold, champagne gold, nickel, gunmetal; matte/brushed/glossy) based on the approved sample. During sampling, we confirm hardware color using real plated pieces—not photos—and check under the same lighting used for leather approval to avoid warm/cool tone mismatch. For bulk production, we lock the hardware supplier, plating specification, and color standard, then verify incoming hardware against the approved reference before assembly. If leather tone is updated, we re-confirm hardware plating to keep the overall color harmony consistent.

Elevate Your Brand with Mherder

Get a practical buyer-focused report covering category trends, price positioning, and competitive benchmarks for leather bags and small leather goods. Built for importers, brand owners, retailers, and Amazon sellers who need faster product decisions and more reliable sourcing. Download the report to plan your next season with clearer direction.

Customer Testimonials

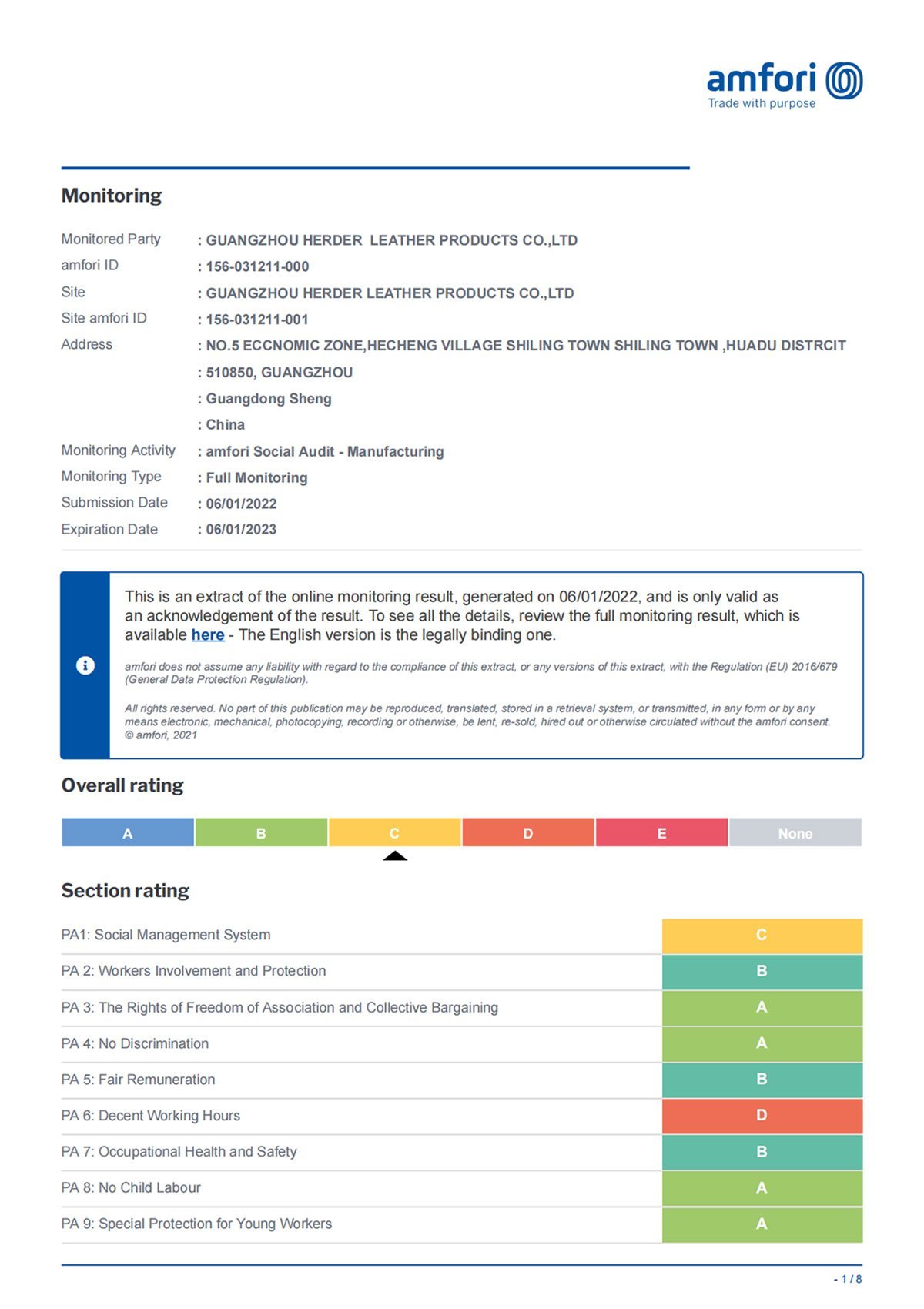

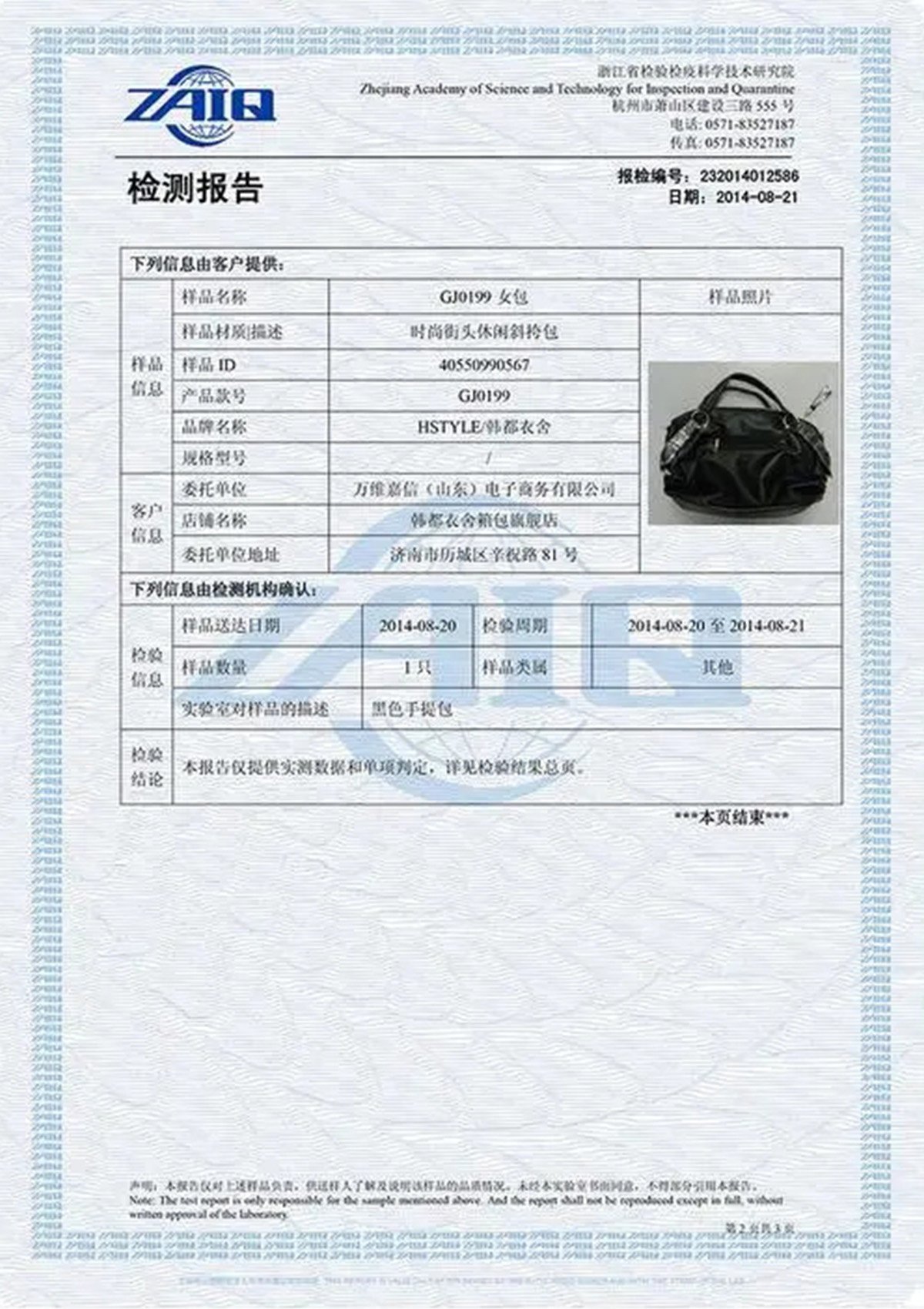

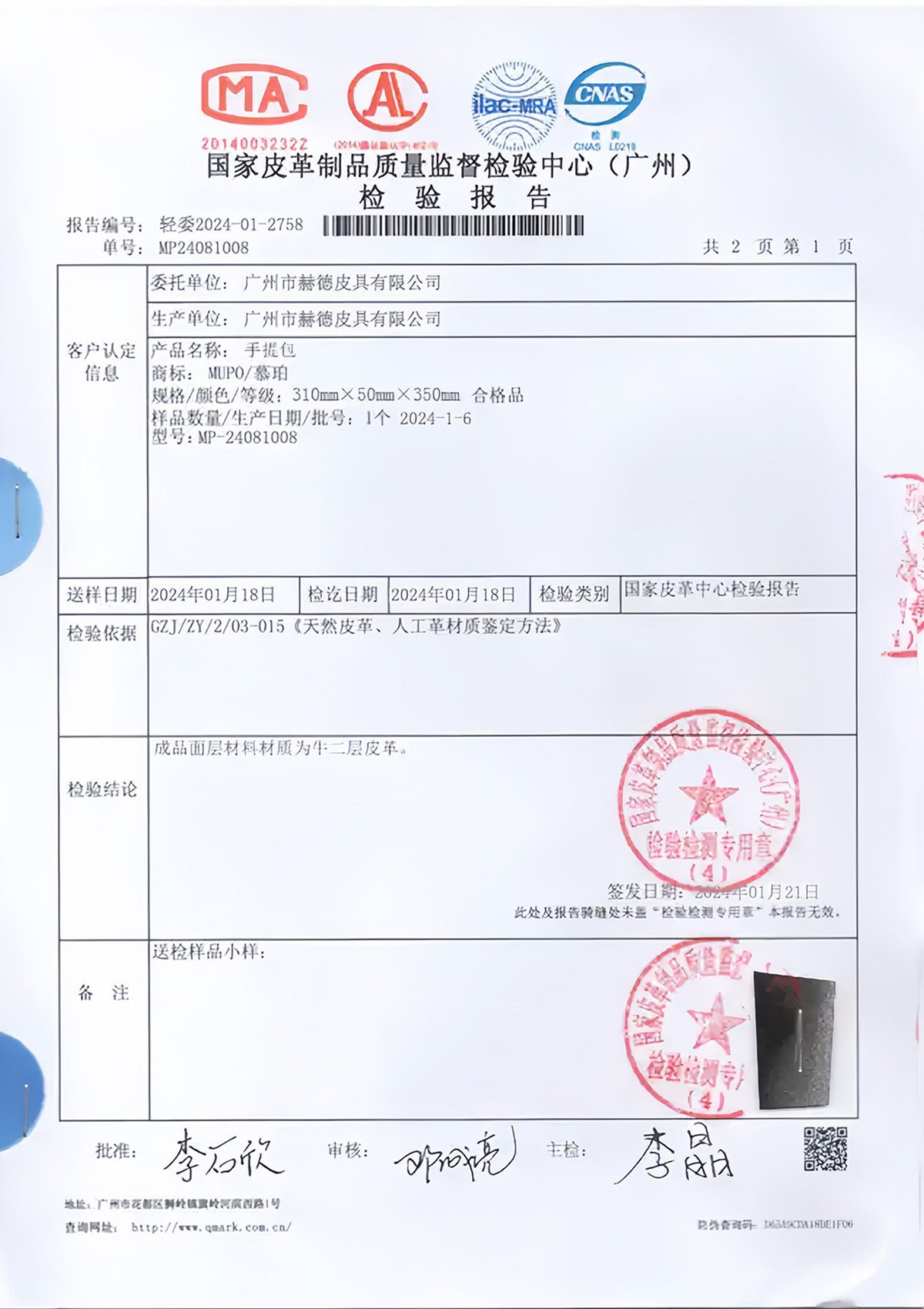

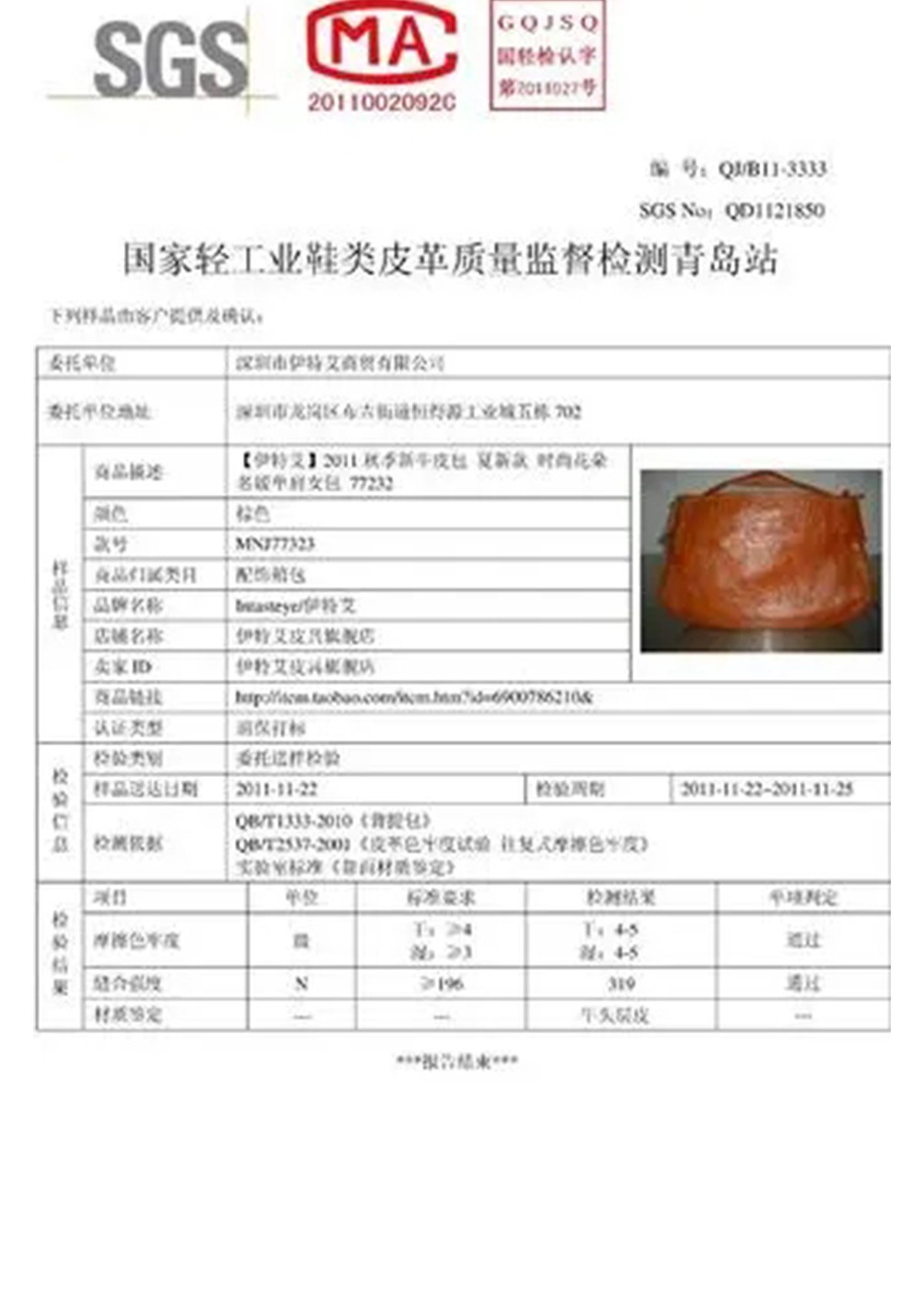

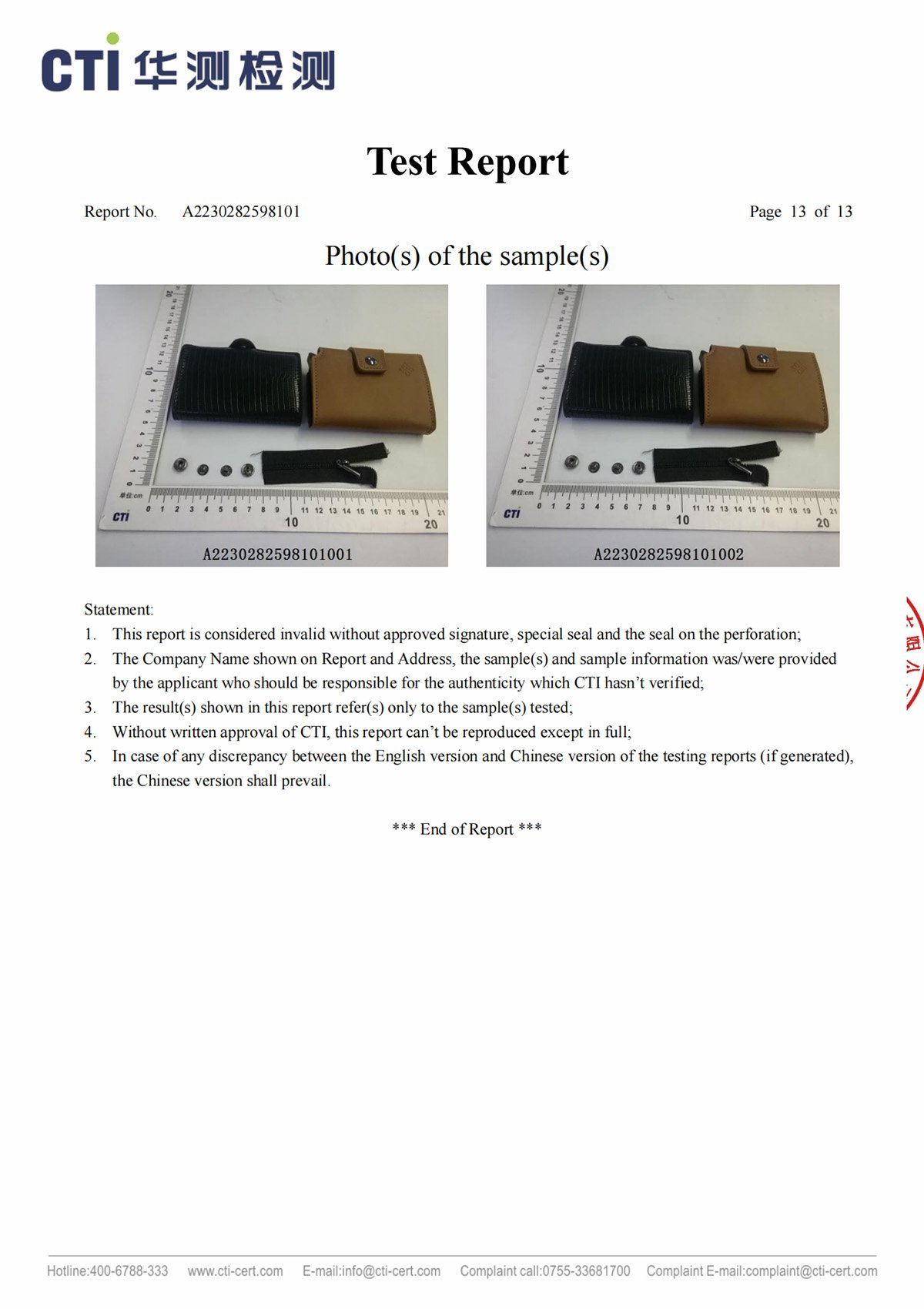

Our Cetificate/Inspection Report

Recent Related Articles

How to Start Your Project

Welcome to our premier leather goods manufacturing company based in Guangzhou. We take great pride in specializing in the production of top-quality leather goods, meticulously crafted with premium genuine leather materials. Over the past 18 years, we’ve honed our expertise in providing customized leather goods solutions, showcasing our dedication to fine craftsmanship and ensuring utmost customer satisfaction. How can we assist you today?