Magnetic Wallet OEM Manufacturing & Specification Overview

Magnetic wallets are compact cardholders designed to attach securely to magnetic phone cases or magnetic mounting surfaces. They are widely used in retail accessory lines, private-label programs, and corporate gifting ranges where a clean silhouette, consistent fit, and stable repeat supply are required. Compatible with MagSafe-style magnetic phone cases; other magnetic-compatible cases can be verified during sampling.

Our core lineup focuses on slim magnetic wallet formats with standardized dimensions for stable ordering and assortment planning. Material options include genuine leather (full-grain/top-grain/corrected options) and selected PU/microfiber alternatives, offered in core colors like black and brown, with custom color matching supported.

Production follows buyer-approved specifications—material selection, magnetic module structure, alignment tolerance, edge finishing, stitch density, logo method, and packaging—then stays locked for repeat orders. Mherder supports OEM/ODM development, sampling, bulk production, and replenishment programs through in-house pattern engineering and manufacturing.

- Formats: Slim magneticcard wallet / magneticwallet with stand (optional)

- Capacity: Typically 2–4 cards (by model + material thickness)

- Size: Standardized program dimensions; custom size supported for private label

- Materials: Genuine leather + PU/microfiber options (by target price tier)

- Magnetic Module: Built-in magnet array + alignment structure (locked by approved sample)

- Fit Standard: Attachment strength and alignment tolerance controlled per batch (per approved reference)

- Optional Features: RFID layer, finger strap, pull-tab, ID window, stand function

- Finishing: Edge paint or turned edges; stitching density locked by spec

- Branding: Deboss/emboss/foil/metal logo plate/woven label

- Packaging: Polybag/dust bag/gift box/retail sleeve (custom supported)

Magnetic Wallet Structure & Attachment Engineering

Magnetic wallets are developed as slim, collection-readycardholders with a clean exterior and a stable magnetic attachment. Each model is designed around three priorities: secure magnetic hold, controlled alignment on the phone case, and a refined finish suitable for premium accessory collections.

The wallet structure integrates a fixed magnetic module to support consistent attachment strength across production runs. Interior storage is optimized for everyday carry, typically holding essential cards in a compact layout. Materials are offered in genuine leather and selected PU/microfiber alternatives, with controlled grain and surface finishing to keep color tone and handfeel consistent across batches.

To maintain durability and shape, key stress zones are reinforced, edges are finished to specification (edge paint or turned edges), and stitch density is controlled for neat, repeatable workmanship. The outcome is a slim, branded accessory built for stable OEM supply and long-term replenishment.

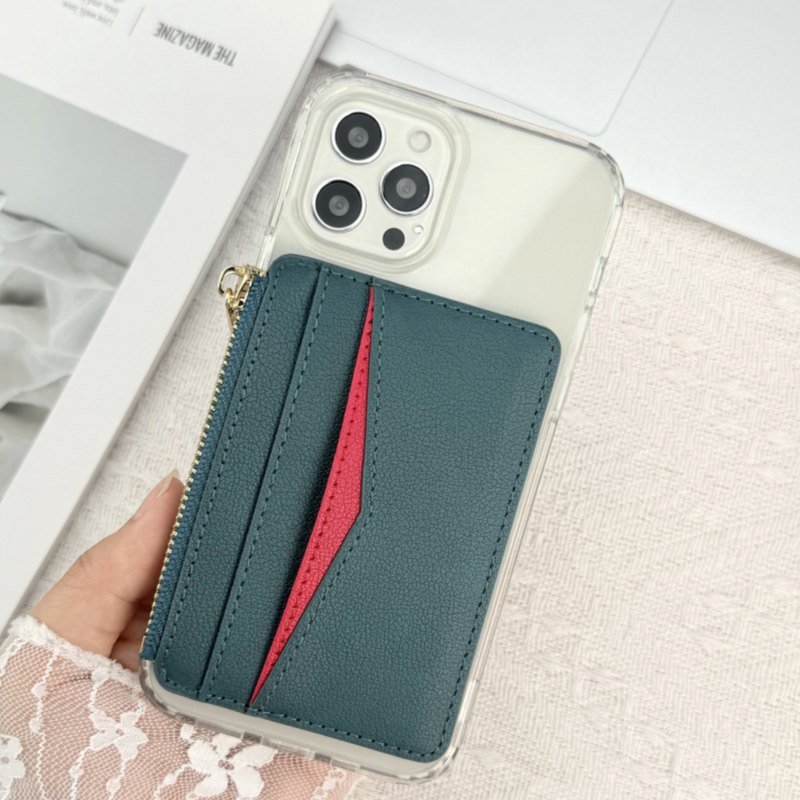

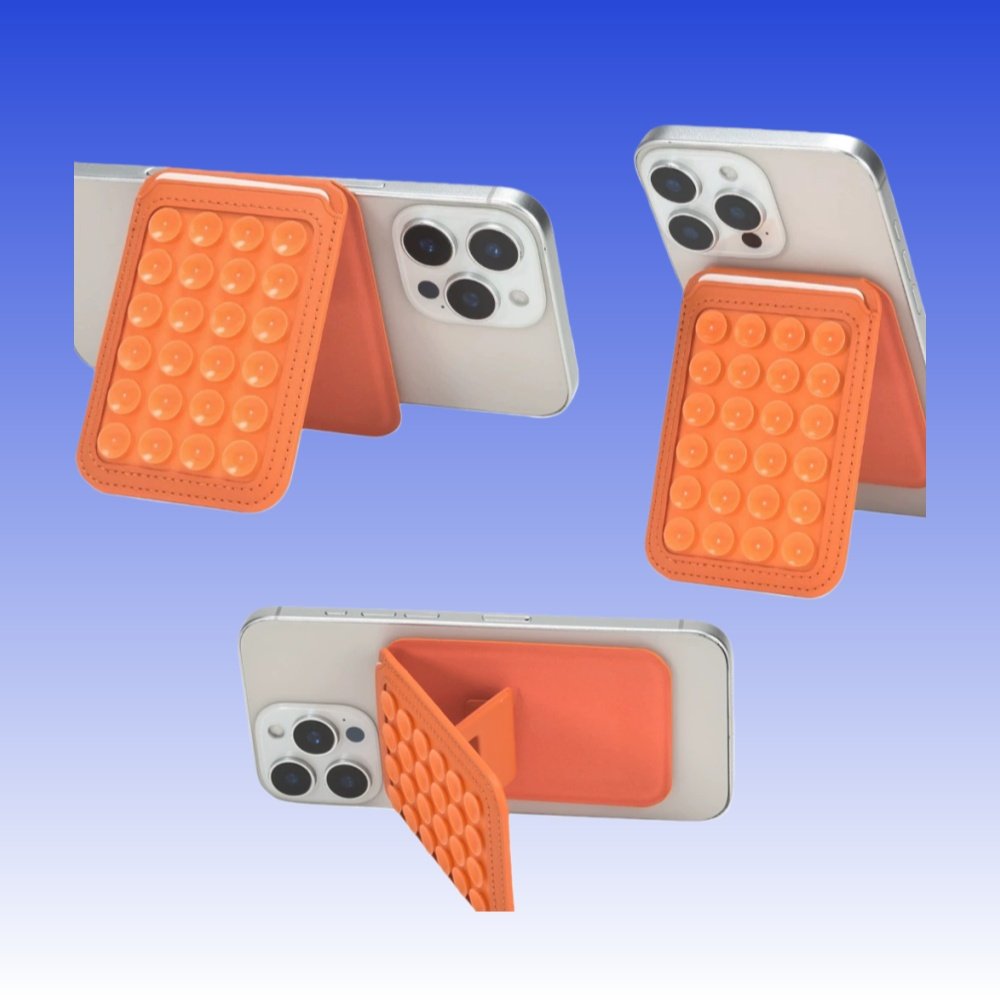

Types of Premium Magnetic Wallet We Produce

One-Stop OEM/ODM Solutions for Custom Leather Products

Magnetic Wallet Bulk Programs for Stable Sourcing

Bulk magnetic wallet programs depend on clear specifications and stable assortment planning. The following points show how this lineup supports steady sourcing and simplified purchasing:

- Defined format standards

To avoid SKU confusion, models are built in fixed magneticwallet formats with standardized dimensions, making assortments easier to manage across catalogs and retail displays. - Material options matched to pricing tiers

Use one supply program to cover entry-level, mid-range, and premium positioning with genuine leather and selected PU/microfiber alternatives based on target cost and market requirements. - Stable magnetic attachment and alignment control

Attachment feel is controlled by locking the magnetic module structure and alignment reference. This reduces variation between batches and helps keep user experience consistent. - Coordinated finishes across collections

Core tones (black, brown) and approved custom colors are controlled using reference standards, helping repeat orders match earlier deliveries in retail presentation. - Private-label development support

Beyond standard styles, we support structure adjustments (capacity/shape/stand function), branding methods, and packaging formats so retail and gifting programs can be produced under the same locked specification.

Manufacturing Control for Stable Magnetic Wallet Programs

Choosing a magnetic wallet supplier is typically a long-term program decision. Once a style is approved, dimensions, attachment performance, and finish consistency must remain stable across repeat orders. Our production practices are structured around that requirement:

- Locked format references

Approved samples are kept as production standards. Each order follows the same dimensions, layout, and magnetic module reference to keep repeat deliveries consistent. - Magnetic module alignment control

Magnetic components are installed using fixed positioning and alignment standards. This helps keep the attachment feeling stable and reduces shifts or mismatches between production runs. - Finish and surface consistency

We check each lot for color tone, grain appearance, and edge finishing. This keeps retail lines and private-label programs consistent across seasons and replenishment orders. - Program-based capacity planning

Active wallet styles are scheduled as ongoing programs rather than one-off jobs. New colors, variants, or volume increases can be added without restarting development, supporting replenishment and long-term supply.

Sampling, MOQ & Production Lead Time Overview

• Sampling: Prototype and pre-production samples available for material, fit/attachment feel, branding, and finishing approval

• Sample lead time: Typically 7–15 business days (depends on structure + materials)

• MOQ: We can propose 2 MOQ options: RTS small-batch for testing, and program MOQ for custom development based on confirmed specs.

• Bulk lead time: Typically 25–40 days after sample approval (depends on order qty + season capacity)

• Quality standard: Production follows approved “gold sample” and locked spec for repeat orders

• Shipping: Consolidated shipments supported; express/air/sea options available upon request. Shipping terms: EXW / FOB Guangzhou / DDP available upon request.

Confidentiality & IP Protection

We are prepared to sign confidentiality and non-disclosure agreements (NDA) to protect your drawings, technical files, and product concepts throughout the development and production process.

• Confidentiality Agreement Ready: We can sign a formal confidentiality agreement before receiving or reviewing any design files, tech packs, or technical documents.

• NDA Available Upon Request: We can sign an NDA provided by you, or we can provide our standard NDA template for review and signature.

• Secure File Handling: All drawings, measurements, and brand assets are securely stored and accessed only by authorized project teams.

• All customer designs and development information are treated as confidential and are not shared with third parties.

Wait! Don't Miss Out!

Still not finding what you’re looking for? Contact our consultants for more available products.

FAQ

Standard options include slim magnetic card wallets. Variants such as stand-supported designs or alternative shapes can be developed for private-label projects.

Genuine leather and selected PU/microfiber options can be produced under one program, supporting different price tiers with the same supplier.

We support deboss/emboss, foil stamping, metal logo plates, woven labels, and retail packaging customization.

We lock specifications based on the approved sample, including dimensions, magnetic module structure, alignment reference, finishing method, and workmanship standards. Repeat batches follow the same production reference.

These wallets are designed for magnetic-compatible phones and cases. For best performance, we recommend testing with your target case type during sampling, then locking the fit standard for production.

RFID blocking layers can be integrated depending on the selected layout and thickness requirement. We will confirm the structure impact during sampling.

Different formats, colors, and materials can be consolidated under one production plan and shipped together to simplify purchasing and inventory coordination.

We provide prototype and pre-production samples for material, structure, branding, fit/attachment feel, and finishing approval. Bulk production starts only after final spec confirmation.

We support both initial bulk launches and ongoing replenishment quantities. Capacity can be arranged for wholesale, retail collections, and promotional programs.

To maintain stable attachment performance, appearance consistency, and repeat-order reliability, magnetic wallet production follows fixed quality checkpoints across materials, magnetic module assembly, and finishing stages.

- Magnetic Strength & Attachment Stability

Magnetic modules are tested against internal attachment benchmarks using approved reference samples. This helps maintain consistent holding force and user attachment feel across production batches. - Magnetic Alignment Accuracy

Magnet module positioning is controlled using pattern reference tooling and assembly guides. Alignment tolerance is checked during production to reduce shift and ensure stable positioning on magnetic-compatible surfaces. - Card Slot Tension & Fit Consistency

Card slot tightness is checked using standard card gauges. This helps maintain balanced card retention — not too loose for drop risk, and not too tight for usability. - Edge Finishing Durability

Edge paint adhesion, thickness, and smoothness are visually and manually checked. Flex testing is performed to reduce cracking risk during daily bending and handling. - Surface & Color Consistency

Leather grain appearance, color tone, and surface finishing are checked against approved master samples to maintain retail display consistency across repeat batches. - Stitching & Assembly Workmanship

Stitch density, stitch line straightness, and reinforcement zones are checked during in-line QC and final inspection to ensure repeatable workmanship quality.

Customer Testimonials

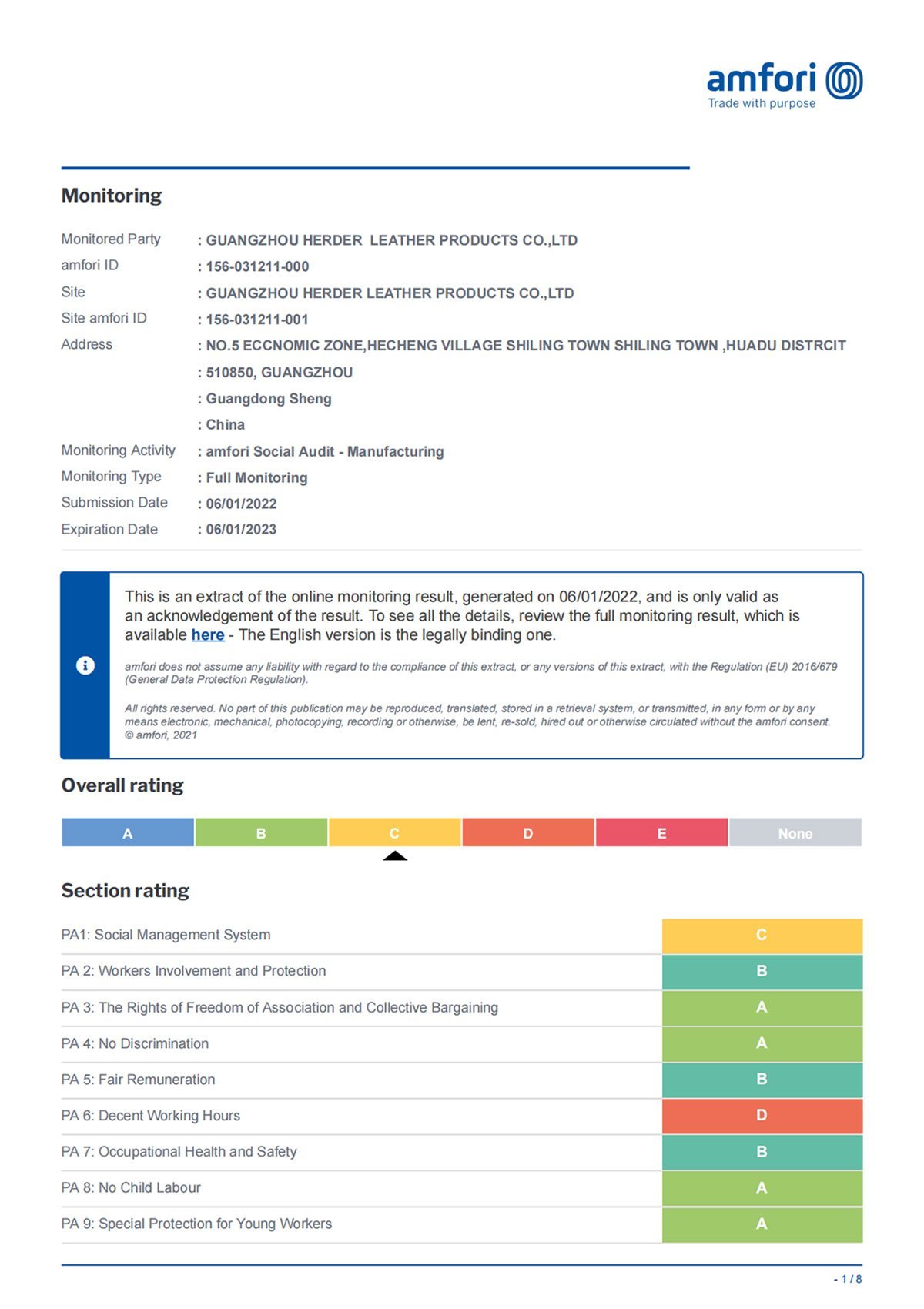

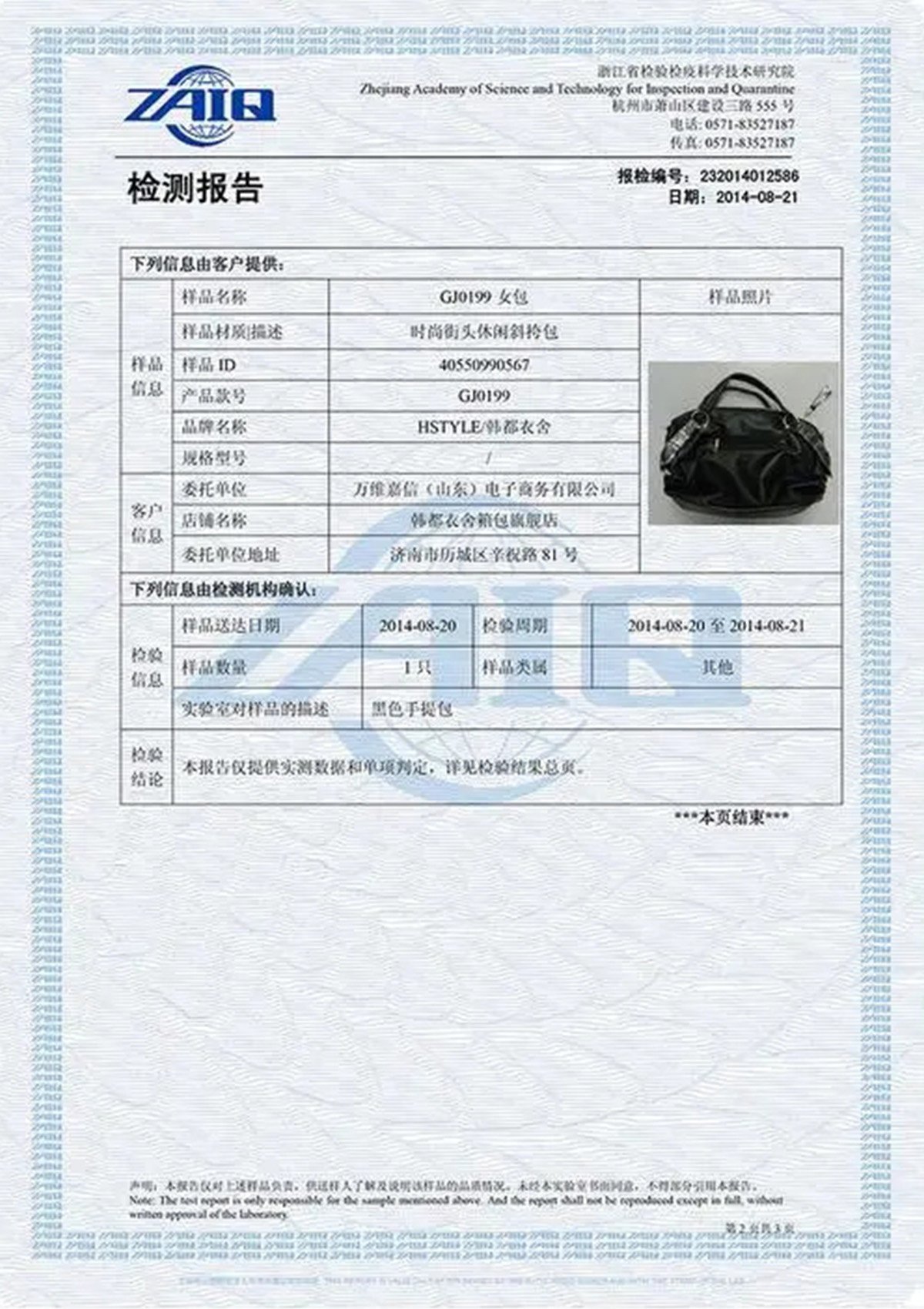

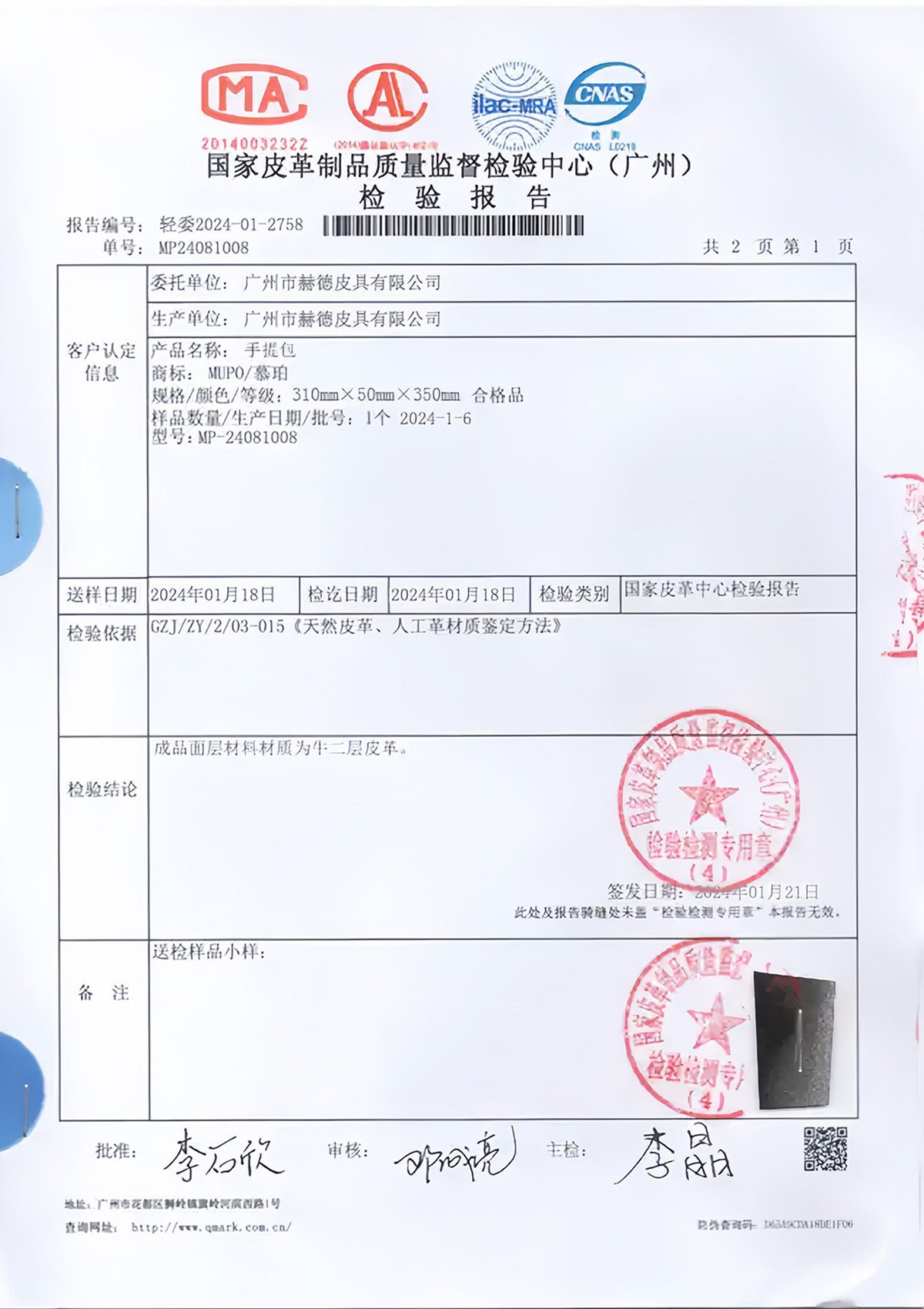

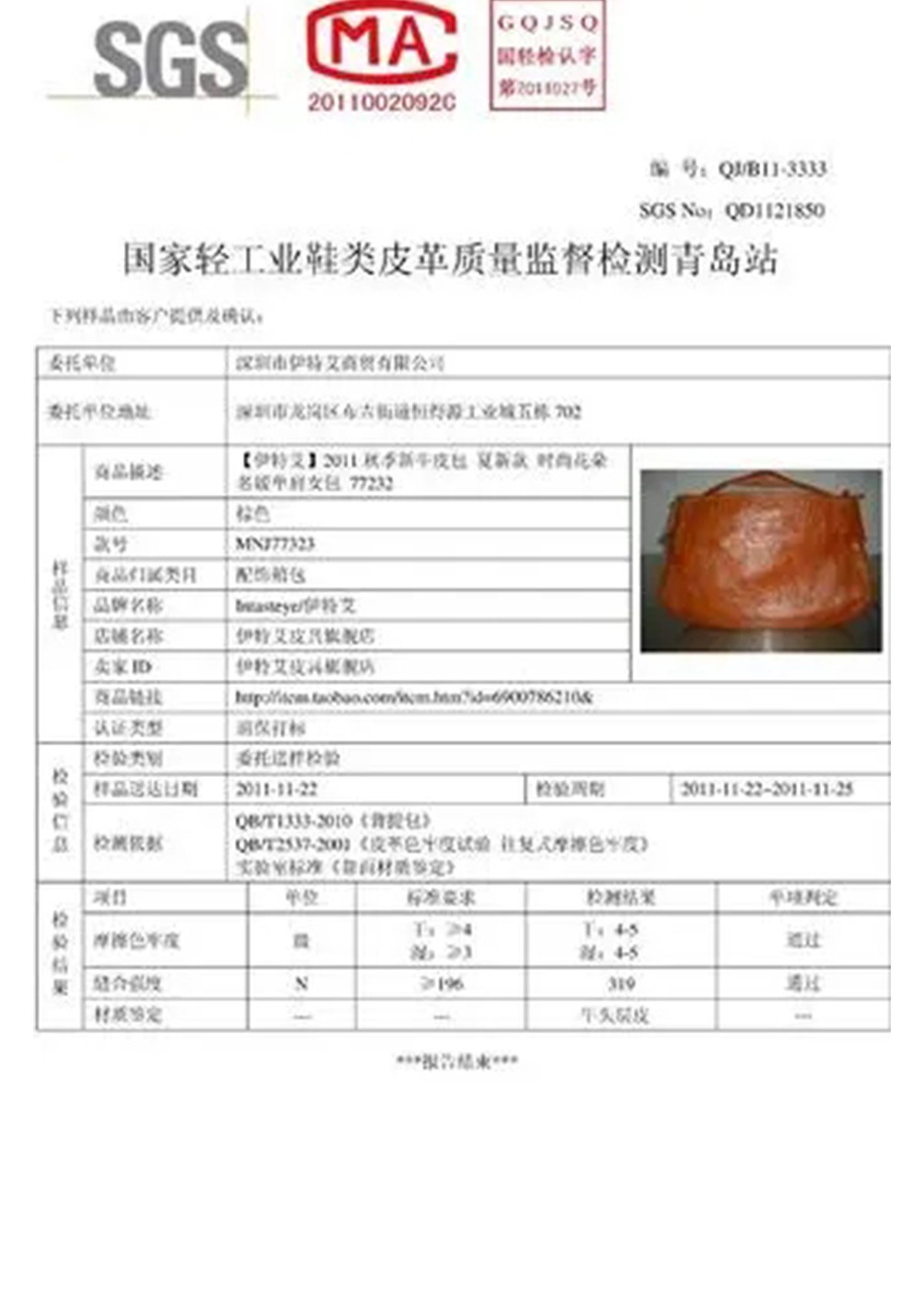

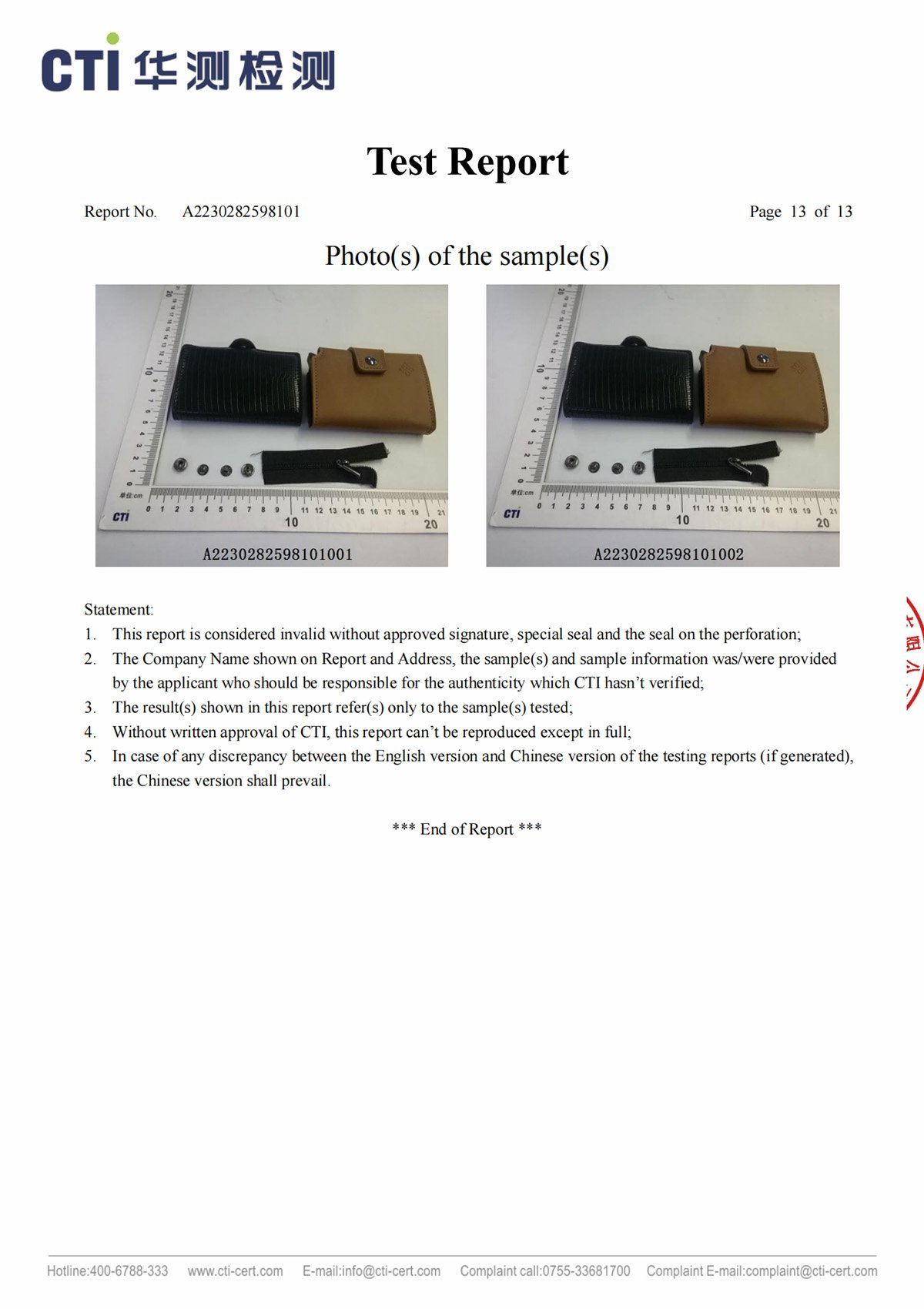

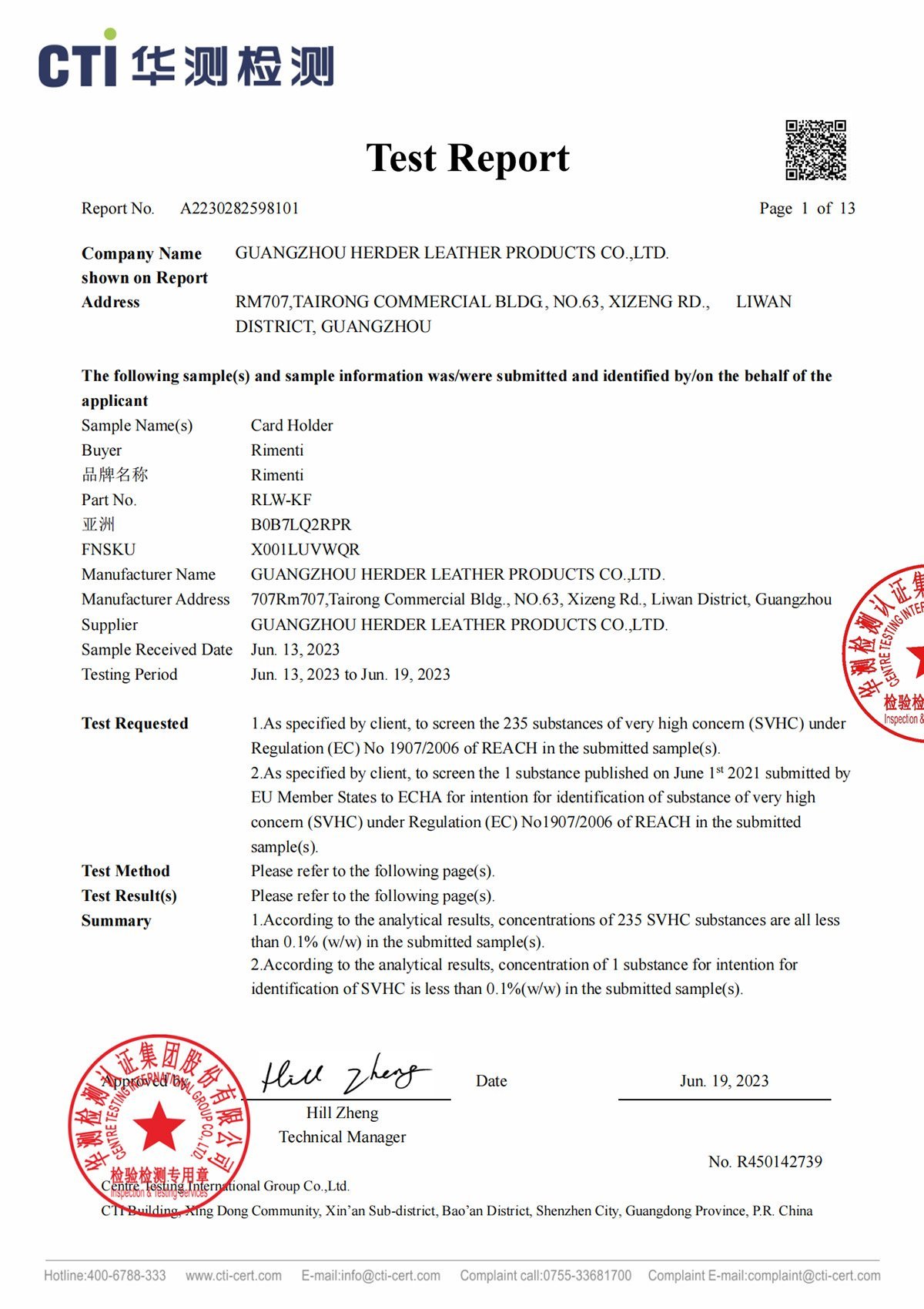

Our Certificate/Inspection Report

Recent Related Articles

Welcome to our premier leather goods manufacturing company based in Guangzhou. We take great pride in specializing in the production of top-quality leather goods, meticulously crafted with premium genuine leather materials. Over the past 18 years, we’ve honed our expertise in providing customized leather goods solutions, showcasing our dedication to fine craftsmanship and ensuring utmost customer satisfaction. How can we assist you today?