Introduction

Leather goods manufacturing is a sophisticated industry that combines traditional craftsmanship with modern technology to produce a wide range of products. Whether you’re an importer, brand owner, Amazon big buyer, retailer, wholesaler, or another B-side customer, understanding the intricacies of this process can help you make informed decisions for your business. In this article, we’ll delve into the 30 Frequently Asked Questions about leather goods manufacturing, providing you with the ultimate guide to navigating this dynamic market.

Table of Contents

ToggleWhat is leather goods manufacturing?

Leather goods manufacturing involves the creation of products made from animal hides, primarily from cattle. This process includes several stages, from sourcing raw materials to designing, producing, and finishing items such as bags, wallets, belts, and shoes. Manufacturers combine traditional techniques with modern machinery to ensure quality and durability in their products. Learn more about the basics of leather goods manufacturing.

What types of leather are used in manufacturing?

Various types of leather are utilized in manufacturing, each offering distinct characteristics. Common types include full-grain leather, top-grain leather, genuine leather, and bonded leather. Full-grain leather is prized for its durability and natural appearance, while bonded leather is a more affordable option made from recycled scraps. The choice of leather depends on the desired quality, price point, and end-use of the product. Explore different leather types.

What are the main products produced in leather goods manufacturing?

Leather goods manufacturing produces a wide array of products, including handbags, wallets, belts, shoes, jackets, and accessories like keychains and phone cases. High-end brands often focus on luxury items, while others may produce more utilitarian products. The versatility of leather allows manufacturers to cater to diverse markets and consumer preferences. Discover popular leather products.

Materials and Sourcing

Where do manufacturers source their leather?

Manufacturers source leather from various regions known for their high-quality hides, such as Italy, China, India, and the United States. The choice of source depends on factors like quality, availability, cost, and ethical considerations. Sustainable sourcing is increasingly important, with many manufacturers seeking suppliers that adhere to environmentally friendly practices. Find reputable leather suppliers.

What factors influence the quality of leather used?

Several factors influence leather quality, including the type of hide, tanning process, thickness, and finish. Full-grain leather, for example, retains the natural texture and is more durable, while the tanning process can affect the leather’s color, softness, and resistance to water. Proper storage and handling also play crucial roles in maintaining leather quality. Understand leather quality factors.

Are there sustainable or eco-friendly leather options available?

Yes, the industry is moving towards more sustainable and eco-friendly leather options. Vegetable-tanned leather, for instance, uses natural tannins from plants, reducing the reliance on harmful chemicals. Additionally, some manufacturers use recycled leather or adopt practices that minimize waste and environmental impact. Consumers are increasingly seeking eco-friendly products, making sustainability a key trend in the market. Learn about sustainable leather.

Design and Development

How are designs for leather goods created?

Designs for leather goods are created through a collaborative process involving designers, engineers, and marketing teams. It begins with brainstorming ideas and sketching concepts, followed by creating detailed specifications and prototypes. Advanced software tools are often used to visualize designs and make necessary adjustments before production begins. Explore the design process.

What role does prototyping play in the manufacturing process?

Prototyping is essential in leather goods manufacturing as it allows designers to test and refine their concepts before mass production. It helps identify potential issues, improve functionality, and ensure that the final product meets quality standards. Prototypes also serve as a reference for manufacturers and can be used for marketing and presentation purposes. Understand the importance of prototyping.

How long does the design phase typically take?

The design phase can vary depending on the complexity of the product and the manufacturer’s workflow. On average, it may take anywhere from a few weeks to several months. Factors such as the number of revisions, availability of materials, and the efficiency of the design team can influence the timeline. Learn about design timelines.

Manufacturing Processes

What are the main steps involved in leather goods manufacturing?

The main steps in leather goods manufacturing include sourcing and selecting leather, designing and prototyping, cutting and shaping, stitching and assembling, adding hardware and embellishments, finishing, and quality control. Each step requires precision and expertise to ensure the final product meets the desired standards—a detailed manufacturing process.

How is leather treated and prepared for production?

Leather is treated and prepared through processes like cleaning, conditioning, and tanning. Cleaning removes impurities, while conditioning ensures the leather remains supple. Tanning stabilizes the leather, preventing it from decomposing and enhancing its durability and appearance. Different tanning methods, such as chrome tanning or vegetable tanning, are chosen based on the desired properties of the final product. Learn about leather treatment.

What machinery is essential for manufacturing leather goods?

Essential machinery for leather goods manufacturing includes cutting machines, stitching machines, edge finishing machines, and embossing equipment. Advanced tools like laser cutters and computerized sewing machines enhance precision and efficiency. Additionally, machinery for adding hardware, such as rivets and zippers, is crucial for assembling various components of the products. Explore essential manufacturing machinery.

How is stitching performed to ensure durability?

Stitching is performed using high-quality threads and durable stitching techniques such as saddle stitching, which involves using two needles for each stitch. This method ensures that the seams are strong and can withstand regular use. Precision stitching machines or skilled hand stitching are employed to maintain consistency and durability in the final product. Understand stitching techniques.

What methods are used for adding hardware and embellishments?

Adding hardware and embellishments involves attaching elements like zippers, buckles, clasps, and decorative studs. These are typically secured using specialized machinery or hand tools to ensure they are firmly attached. Embellishments can also include embossing, engraving, or applying decorative stitching to enhance the aesthetic appeal of the leather goods. Learn about hardware and embellishment methods.

Quality Control

What quality standards are followed in leather goods manufacturing?

Manufacturers adhere to various quality standards to ensure their products meet industry and consumer expectations. These include ISO standards, which provide guidelines for quality management systems, as well as specific industry standards related to durability, safety, and performance. Compliance with these standards helps maintain consistency and reliability in the products. Discover quality standards.

How is quality control maintained throughout production?

Quality control is maintained through regular inspections and testing at each stage of production. This includes checking the raw materials, monitoring the manufacturing processes, and conducting final product inspections. Implementing standardized procedures and using quality management systems help identify and address issues promptly, ensuring that only high-quality products reach the market. Learn about quality control processes.

What are common defects in leather goods, and how are they addressed?

Common defects in leather goods include stitching errors, inconsistent coloring, scratches, and hardware malfunctions. These defects are addressed through meticulous quality inspections and by implementing corrective measures during production. Training workers to maintain high standards and using advanced machinery can also reduce the occurrence of defects. Identify and fix common defects.

Labor and Workforce

What skills are required for workers in leather goods manufacturing?

Workers in leather goods manufacturing need a combination of technical skills and craftsmanship. This includes proficiency in sewing, cutting, and assembling leather, as well as an eye for detail and quality. Knowledge of design principles and the ability to operate specialized machinery are also important. Additionally, problem-solving skills and the ability to work efficiently in a team are highly valued. Explore required skills.

How do manufacturers ensure worker safety and training?

Manufacturers ensure worker safety by adhering to occupational health and safety regulations, providing protective equipment, and maintaining a clean and organized workspace. Regular training programs are conducted to educate workers on safe practices, proper machinery operation, and emergency procedures. Creating a culture of safety helps prevent accidents and promotes a healthy working environment. Learn about worker safety.

What are the labor costs associated with manufacturing leather goods?

Labor costs in leather goods manufacturing vary based on factors such as location, skill level, and production volume. Higher-skilled workers command higher wages, and regions with higher living costs will have increased labor expenses. Additionally, investing in training and maintaining a skilled workforce can impact overall costs but contribute to higher-quality products. Understand labor cost factors.

Technology and Innovation

How is technology integrated into leather goods manufacturing?

Technology is integrated through the use of advanced machinery, computer-aided design (CAD) software, and automation systems. These technologies enhance precision, increase production efficiency, and allow for greater customization. Innovations like laser cutting and 3D printing are also being adopted to streamline processes and create intricate designs with ease. Explore technology in manufacturing.

What innovations are shaping the future of the industry?

Innovations such as sustainable tanning methods, smart textiles, and wearable technology are shaping the future of leather goods manufacturing. Additionally, advancements in automation and artificial intelligence are improving production efficiency and quality control. The rise of e-commerce and digital marketing tools also influences how manufacturers reach and engage with their customers. Discover industry innovations.

Are there any advancements in sustainable manufacturing practices?

Yes, there are significant advancements in sustainable manufacturing practices, including the use of eco-friendly tanning agents, recycling leather scraps, and reducing water and energy consumption. Manufacturers are also adopting circular economy principles, where products are designed for longevity and recyclability. These practices not only minimize environmental impact but also appeal to increasingly eco-conscious consumers. Learn about sustainable practices.

Cost and Pricing

What factors influence the cost of manufacturing leather goods?

Several factors influence manufacturing costs, including the quality and type of leather, labor expenses, production volume, and the complexity of designs. Additional costs may arise from customization options, shipping, and compliance with quality standards. Economies of scale can also affect pricing, with larger orders often benefiting from lower per-unit costs. Understand cost factors.

How is pricing determined for finished products?

Pricing for finished products is determined by calculating the total production costs and adding a profit margin. Factors such as market demand, brand positioning, competitor pricing, and perceived value also play a role. Manufacturers must balance affordability with quality to attract their target customers while ensuring profitability. Learn about pricing strategies.

What are the challenges in managing production costs?

Managing production costs involves balancing quality with affordability, optimizing resource usage, and minimizing waste. Fluctuations in raw material prices, labor costs, and supply chain disruptions can also pose challenges. Implementing efficient production processes and leveraging technology can help mitigate these issues and maintain cost-effectiveness. Explore cost management challenges.

Distribution and Market

How are leather goods distributed to retailers or consumers?

Leather goods are distributed through various channels, including wholesale distribution to retailers, direct sales via e-commerce platforms, and partnerships with online marketplaces like Amazon. Some manufacturers also establish their own retail stores or collaborate with distributors to reach a broader audience. Efficient logistics and reliable shipping partners are crucial for timely and safe delivery. Discover distribution methods.

What are the primary markets for leather goods?

The primary markets for leather goods include fashion retailers, specialty boutiques, online marketplaces, and direct-to-consumer brands. Additionally, sectors such as hospitality and corporate gifting also represent significant markets. Geographic markets vary, with regions like North America, Europe, and Asia being major consumers of high-quality leather products. Learn about primary markets.

How do manufacturers stay competitive in the market?

Manufacturers stay competitive by continuously innovating, maintaining high-quality standards, and offering unique designs. Building strong relationships with suppliers and distributors, optimizing production processes, and adopting sustainable practices also contribute to competitiveness. Additionally, effective marketing and understanding consumer trends help manufacturers adapt and thrive in a dynamic market. Explore competitiveness strategies.

Packing

What are the best practices for packing leather goods to ensure quality during transport?

Best practices for packing leather goods include using protective materials such as acid-free tissue paper, sturdy boxes, and cushioning materials to prevent damage during transit. Each item should be individually wrapped and secured to avoid scratches and deformation. Additionally, clear labeling and using tamper-evident seals can enhance the security and presentation of the products upon arrival. Learn packing best practices.

What materials are commonly used for packing leather products?

Common packing materials for leather products include corrugated cardboard boxes, bubble wrap, foam inserts, and protective bags. Sustainable options like recycled cardboard and biodegradable packing peanuts are also gaining popularity. High-quality packing materials not only protect the products but also contribute to a professional and appealing unboxing experience for customers. Discover packing materials.

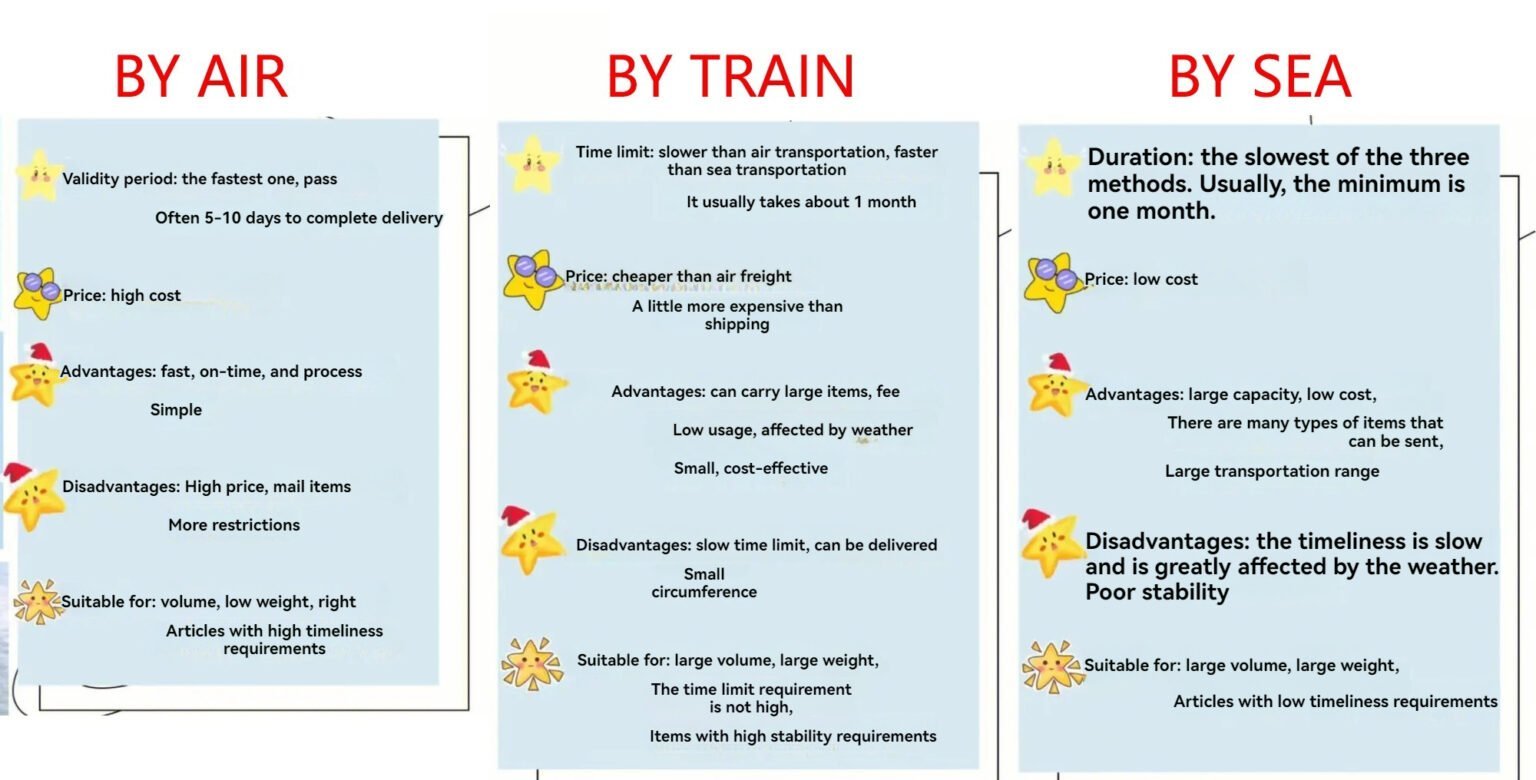

Shipping

How do manufacturers choose the right shipping partners for leather goods?

Manufacturers choose shipping partners based on factors like reliability, cost, speed, and the ability to handle specific shipping requirements. It’s important to select partners with experience in handling delicate items and offering tracking services. Building strong relationships with reputable carriers ensures that products are delivered safely and on time, enhancing customer satisfaction. Find reliable shipping partners.

What are the common shipping challenges for leather products and how are they handled?

Common shipping challenges for leather products include damage during transit, delays, and high shipping costs. These challenges are handled by using robust packing methods, selecting reliable carriers, and opting for insurance to cover potential losses. Clear communication with customers regarding shipping times and providing tracking information also help manage expectations and reduce dissatisfaction. Understand shipping challenges.

Trends and Future Outlook

What are the current trends in leather goods manufacturing?

Current trends in leather goods manufacturing include a shift towards sustainable and ethically sourced materials, the integration of smart technology, and an emphasis on customization and personalization. Additionally, minimalist designs and multifunctional products are gaining popularity, catering to consumers’ desire for versatility and simplicity. Explore current trends.

How is the industry expected to evolve in the next decade?

The leather goods industry is expected to evolve with advancements in sustainable practices, increased use of technology for production and customization, and a growing emphasis on circular economy principles. Digital transformation, including e-commerce and digital marketing, will continue to shape how manufacturers reach and engage with customers. Additionally, consumer preferences for high-quality, durable, and ethically produced goods will drive innovation and growth. Learn about the future of the industry.

Conclusion

Understanding leather goods manufacturing is crucial for importers, brand owners, Amazon big buyers, retailers, wholesalers, and other B-side customers aiming to succeed in this competitive market. From sourcing high-quality materials to leveraging advanced technology and maintaining strict quality control, each step plays a vital role in producing exceptional products. For those looking to partner with reliable manufacturers, Bags Plaza offers over 3000+ designs in stock, with a minimum order quantity of 100pcs per shipment, quick shipment, customization options, and affordable prices. Whether you’re seeking to delve deeper into the manufacturing process or find the ultimate supplier for your business needs, this guide serves as a valuable resource. Visit Bags Plaza to explore their extensive range and discover how they can support your leather goods ventures.