Whatever trends come and go, the stature of leather bags remains exquisite and unbeatable. The trend of custom leather bags has become commercial compared to previous times, which makes the bags more accessible and profitable to all. However, with this commercialization, it is of utmost importance to ensure that the manufacturing of custom leather bags remains sustainable and eco-friendly

Suppose you believe that leather bag manufacturing is still adhering to non-sustainable practices. In that case, you have come to the right place to debunk your belief and explore how our brand, Mherder, rigorously follows sustainable and eco-friendly practices in custom leather bag manufacturing. We are more than what we claim!

Customers need to have complete faith in the purchase they are making, and we oath to ensure that we deliver what we promise our products to be. Our custom leather bag manufacturing units religiously follow sustainable protocols and practices to give back not just to our customers but also to the environment.

Delve deeper into the article, and allow us to gain your confidence in how important it is for us to develop and adhere to sustainable practices in custom leather bag manufacturing.

· Importance and Eco-Friendly Trends of Sustainable Practices

Importance of sustainable practices

In consideration of society’s growing concerns about query sustainability, it is important to ensure that reasonable and sustainable measures are taken in custom leather bag manufacturing. The leather industry has been criticized for waste, resource exploitation, and poor working conditions. Nowadays, solutions include ethical sourcing, the use of eco-friendly substitutes, the prevention of waste, and energy-efficient processes.

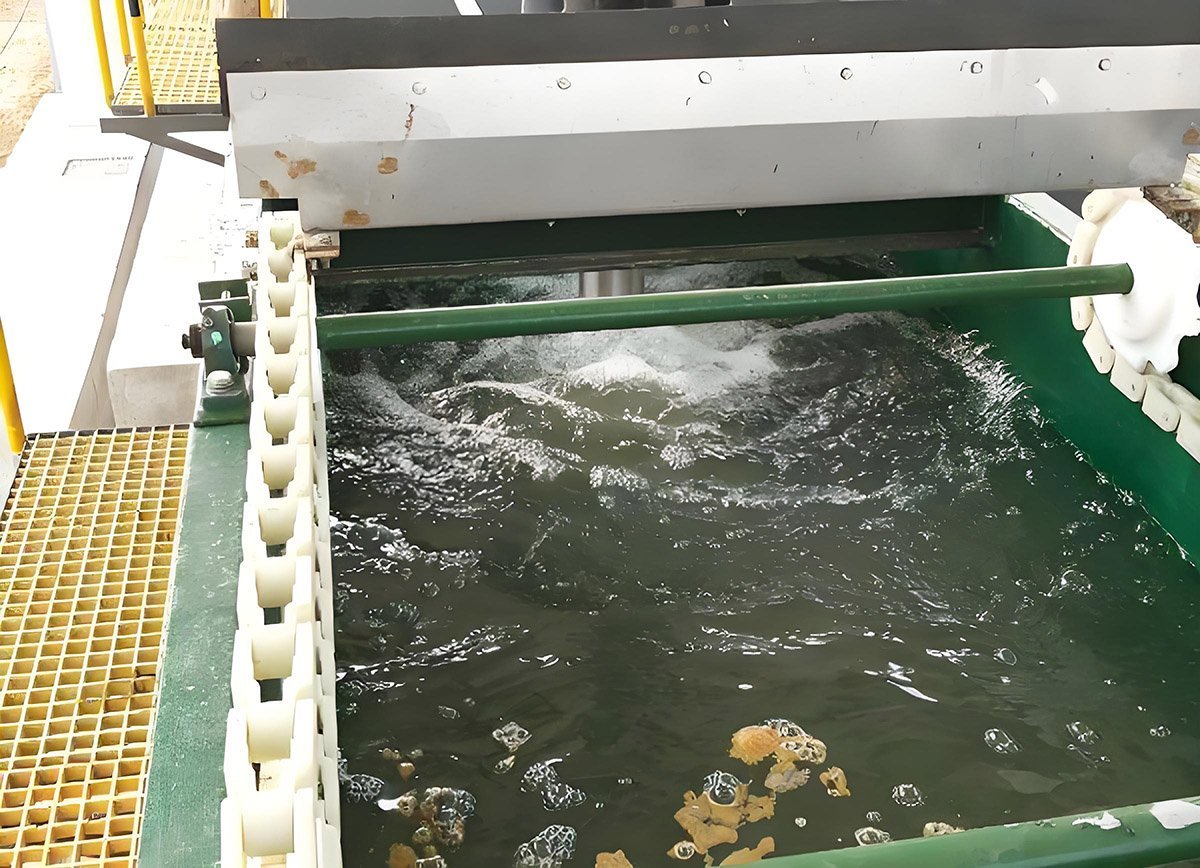

Ethical leather means sourcing leather from the food industry or synthetic leather, which comes from recyclable material or bio-based. Instead of toxic chrome tanning, there is a switch to vegetable tanning, which is environmentally friendly and less toxic. Manufacturers are using closed-loop systems to cut down on water and energy levels and are making use of advanced cutting patterns to minimize waste.

Going green in chemical use is also important where manufacturers use eco-friendly inks to avoid exposing the workers and environment to harm Because fair labor covers not only safe employment conditions and fair pay but also transparent supply chains, grants consumers confidence, and increases sales domains like Leather Working Group promotes the social responsibility housing standards.

Growing Trends of Eco-friendly Manufacturing

Sustainable production practices are on the upward push in one-of-a-kind sectors, mainly because of the development of awareness concerning the sustainable effects of production on the environment. The transition to sustainable improvement is inevitable because of the preference to decrease the carbon footprint, hold sources, and minimize pollution. This exchange isn’t the most effective in revolutionizing industries, but it also impacts the calls for regulation across the world.

Regulations by the government and international treaties are also quite helpful in pushing manufacturers to embrace environmentally sustainable practices. Many other countries have adopted stricter environmental legislation to curb pollution from industries and encourage the utilization of green technologies. Far-reaching strategies such as carbon pricing and those associated with environmental certifications compel organizations to improve their environmental status. Further, there are global policies on climate change, such as the Paris Agreement, that are forcing industries to cut emissions and adopt sustainable production processes.

Global Acceptance of Sustainable Practices

Eco-friendly strategies in producing custom leather bags are progressively integrating into the industry globally due to increasing population awareness concerning ecological and moralistic aspects. The leather goods section of the fashion industry has always faced criticism for the various socio-environmental impacts that have been noted to emanate from operations – be it chemical pollution, wastage of water or poor working conditions. However, as the knowledge of the consumer increases and the awareness to go for environmentally friendly products rises, this industry is changing. New technologies and new laws are also empowering this change towards sustainability.

Customers are now much more conscious of their products’ environmental and ethical effects. This awareness has thus resulted in increased concern in looking for leather products that are manufactured sustainably. As a result, many manufacturers have adopted eco-friendly approaches to their production to fulfill this need, including vegetable-tanned leather, recycling scraps, and pursuing new alternatives such as bio-based fabrics. It is important to note that these approaches also do not harm the environment as much as the traditional approach and produce high-quality, durable products suitable for today’s ethical consumers.

Assistance for sustainable practices is also being received from the international standards and accreditation which has been provided by Leather Working Group. Such certifications aim to guarantee that leather is produced in a sustainable, friendly manner without affecting the social well-being of people in society, thus offering buyers assurance of macular purchases. Also, an increasing number of companies make public the origin of materials they use and how their products are manufactured so that consumers can make informed decisions.

Besides, there are also the economic incentives that are pushing this transition to more sustainability on a global level. Those who go the extra mile to ensure that they practice environmental conservation are easily identified in the market since consumers value the environment. In addition, the reduction of costs such as wastes, energy, and materials also implies over a period that using sustainable manufacturing to produce products is cost-effective. As more and more business establishments come to realize these benefits, sustainability is fast emerging as the new industry norm instead of the exception.

- Top of Form

- Bottom of Form

· Negative Connotations with Non-sustainable Practices

Types of Non-sustainable Practices

Several unsustainable practices have been associated with the manufacturing of custom leather bags for the environmental and social impacts. One of the most significant non-sustainable activities is the application of hazardous substances in leather tanning. Traditional tanning mostly involves the use of chromium salts, which are uneconomical and have adverse effects on water resources. Leather and finishing products are notorious for using large amounts of water to treat and soften leather. Many traditional products also rely on renewable energy sources, such as fossil fuels, contributing to greenhouse gases and climate change. During cutting and processing, waste leather is often discarded as waste. Without proper recycling or waste management practices, these by-products contribute to the growing industrial waste problem, which can take years to break down.

Inspections and Legal Actions Against Non-Sustainable Practices

Inspections and legal movements against non-sustainable practices in custom leather bag manufacturing have emerged as increasingly more commonplace as governments and regulatory bodies work to cope with environmental and social worries. With the rising recognition of the harmful effects of non-sustainable production tactics—which include pollution, helpful resource depletion, and hard work exploitation—governments are taking stricter measures to enforce sustainability standards.

Environmental inspections are often awareness of the damaging chemical approaches used in leather tanning, including the usage of poisonous chromium and other hazardous materials. Regular audits of factories ensure compliance with environmental policies regarding waste control, water treatment, and emissions manipulation. Factories observed violating those requirements face the consequences, fines, or maybe closure, depending on the severity of their non-compliance. In some cases, businesses are required to enforce corrective measures, such as investing in cleaner technology or adopting waste reduction techniques.

Labor situations are also a chief focus of inspections. Authorities display places of work to make sure that workers are treated fairly, paid accurately, and furnished with safe operating environments. Non-compliance in this place can result in fines or sanctions, and organizations can face reputational damage, which may additionally impact their marketplace position.

· Benefits of Custom Sustainable Practices in Leather Bag Manufacturing from the Customer’s Perspective

Customer’s shift from non-sustainable to sustainable approaches

Customers are increasingly moving from non-sustainable to sustainable tactics in custom leather-based bag production, pushed by a growing recognition of environmental and moral issues. Consumers these days prioritize products that mirror their values, looking for brands that offer eco-friendly substances, ethical exertion practices, and transparency in production methods. This shift is essentially stimulated by worries over the damaging results of traditional leather-based manufacturing, consisting of chemical pollutants, aid overuse, and exploitative exertion situations.

Sustainably made leather baggage, often produced by the use of vegetable-tanned leather-based, recycled substances, or alternative green alternatives, attracts consumers who are targeted at decreasing their environmental impact. Additionally, customers are drawn to manufacturers that emphasize truthful wages, secure working conditions, and responsible sourcing. As a result, many groups are adapting to this demand by way of integrating sustainable practices into their production strategies to preserve customer loyalty and align with the broader motion toward sustainability.

This shift benefits each of the surroundings and customers, who advantage of durable, extraordinary products at the same time as contributing to a greater moral and sustainable style industry. Sustainable techniques in custom leather-based bag production are seen to reduce harm even as still presenting luxury and exceptional, making them a compelling preference for modern-day clients.

Perspective and Preferences Towards Sustainable Practices

From the client’s perspective, sustainable practices have grown to be a key component in their shopping selections, particularly in industries like fashion and leather goods. Many consumers now prioritize products that align with their environmental and moral values, seeking out manufacturers that use eco-friendly substances, lessen waste, and ensure truthful labor practices. They view sustainability as now not only a fashion but a responsibility, anticipating companies to limit their environmental impact and sell social responsibility.

Customers recognize transparency in how merchandise is made and like companies that are open approximately their sourcing and manufacturing methods. They are increasingly inclined to pay a top rate for sustainably made merchandise, understanding that these items are regularly of better best, greater long-lasting, and have a decreased environmental footprint. This developing choice for sustainable practices displays a shift in consumer behavior, where ethical considerations play an essential role in defining logo loyalty and purchasing selections.

· China’s Top Sustainable Practices in Custom Leather Bag Manufacturing

China’s Skill Set and Manufacturing Practices

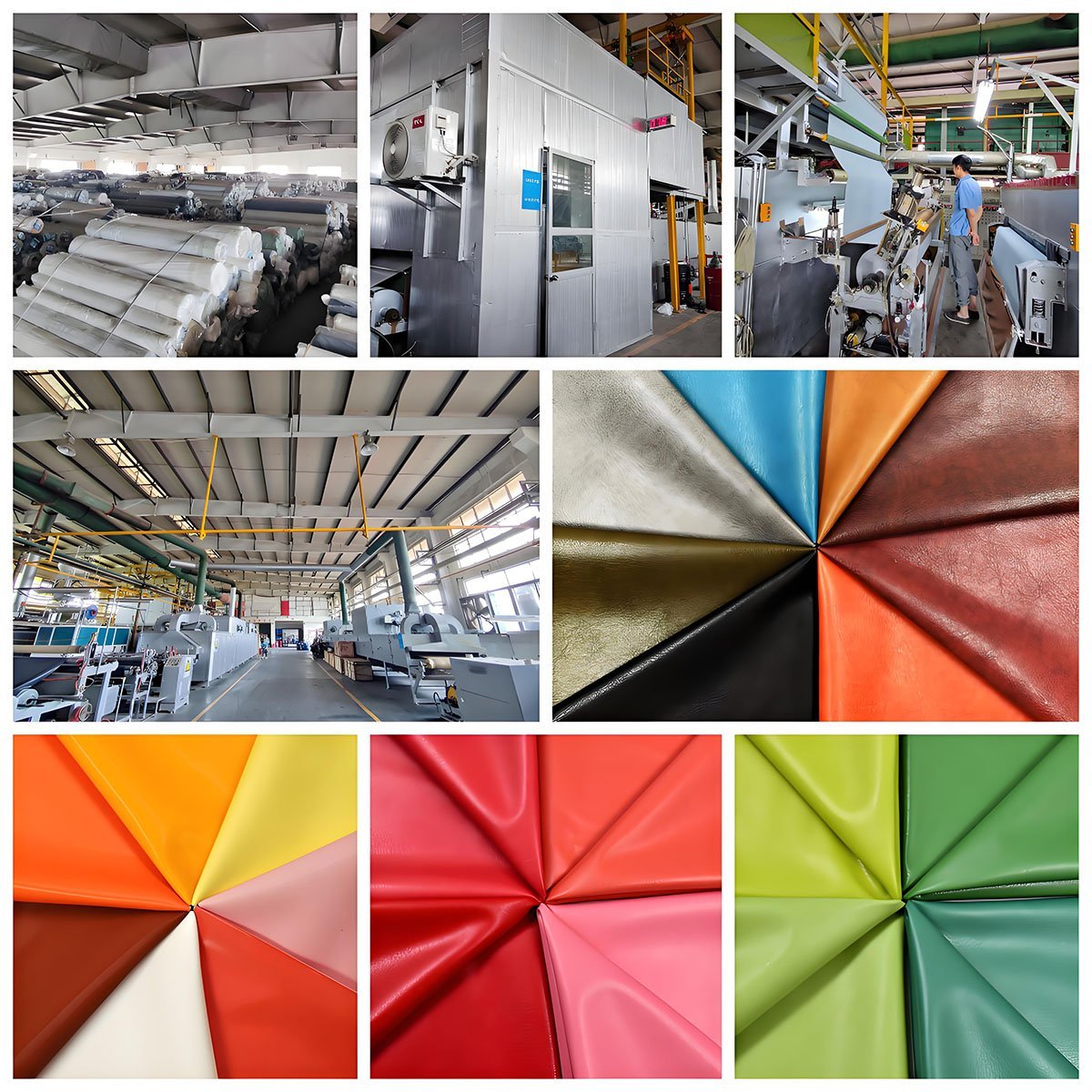

Training and equipping people in China with sustainable production practices is essential. As China remains a central hub for international manufacturing, the adoption of sustainable practices in its factories has tremendous implications for lowering environmental impact and enhancing aid efficiency. By imparting people with vital talents and information, manufacturers can make sure that sustainable strategies are effectively implemented, leading to decreased waste, lower power consumption, and much less pollution.

In essence, equipping employees with sustainable practices now not only allows China to meet international environmental standards but also supports the introduction of a more responsible and efficient production sector.

Mherder’s Take on Sustainable Manufacturing

Mherder is incorporating sustainable practices in custom leather bag production by specializing in several key regions. The emblem makes use of ethically sourced leather-based, making sure that the material comes from responsible suppliers and minimizes environmental effects. We employ vegetable tanning methods instead of dangerous chemical processes, decreasing pollution and chemical use. Additionally, we integrate recycled and green materials into its designs, supporting the minimization of waste. By adopting strength-efficient production techniques and promoting transparency in its supply chain, we oath to demonstrate a dedication to environmental and moral standards in its production practices.

· Conclusion

In conclusion, the movement toward sustainable practices in custom leather bag manufacturing is reshaping the industry by addressing long-standing environmental and ethical concerns. As consumers increasingly demand products that reflect their values, Mherder is leading the way with innovative approaches that emphasize eco-friendly materials, responsible production processes, and ethical labor practices. So, head over to bagsplaza.com in case you’re looking for sustainable yet high-quality custom leather bags.